Views: 222 Author: Tina Publish Time: 2026-01-10 Origin: Site

Content Menu

● Why Extension Cord Size Matters

● Typical Pool Pump Power Requirements

● Why Many Pros Avoid Extension Cords For Pool Pumps

● Understanding Wire Gauge And Amp Rating

● Matching Cord Size To Pump And Distance

● Example Scenarios (Non‑Code Design, Just Practical Guidance)

● Outdoor Safety: GFCI, Grounding And Weather Protection

● What The NEC And Codes Emphasize

● How To Choose A Cord Step‑By‑Step

● When To Stop Using An Extension Cord

● How A Professional OEM Filter & Pump Manufacturer Can Help

● FAQs About Extension Cords And Pool Pumps

>> 1. Can I use a regular household extension cord for my pool pump?

>> 2. Is 14‑gauge wire enough for a pool pump?

>> 3. How far can I run an extension cord to my pool pump?

>> 4. Does my pool pump need to be on a GFCI?

>> 5. Are extension cords allowed permanently on pool pumps?

>> 6. What kind of extension cord should I buy if I must use one?

What size extension cord you need for a pool pump depends on the pump's horsepower/amp draw, the length of the run, and local safety codes, but in most residential cases a short, heavy‑duty outdoor cord of 12 AWG (or thicker 10 AWG for longer runs and higher loads) is the minimum starting point, and long‑term you should plan for a dedicated outlet near the pool instead of relying on an extension cord at all.[1][2]

Running a pool pump through the wrong extension cord is one of the fastest ways to overheat cables, trip breakers, or even damage your motor and create a shock hazard around water. This guide walks through how to choose the right cord size, why cord length matters, and when you should stop using extension cords entirely and upgrade to a permanent, code‑compliant power solution.[2][3][1]

- Pool pumps draw continuous current for many hours, which makes voltage drop and overheating in undersized cords far more likely than with short, intermittent loads.[3][1]

- A cord that is too small in gauge (thin wire) increases resistance, which causes heat in the cord and reduces voltage at the pump, stressing the motor windings and shortening pump life.[1][3]

- Wet environments add shock risk, so you must combine the right wire size with proper grounding, GFCI protection, and outdoor‑rated components.[4][2]

To size an extension cord correctly, you need a basic understanding of your pump's electrical load.[5][6][1]

- Most above‑ground pool pumps are 120 V units with factory cords and draw in the ballpark of 8–15 A depending on horsepower.[6][5][1]

- Common residential in‑ground pumps range roughly from 0.75 HP up to about 3 HP, with higher horsepower models often wired 208–230 V to stay within National Electrical Code (NEC) ampacity limits.[7][5][6]

- As a rough example, a typical 1.5 HP single‑speed pump may use around 1500–2000 W, while a 2 HP pump may reach 2000–2500 W; at 120 V that can mean 15–20 A or more.[8][6]

Although many homeowners do it, most electricians and pool professionals discourage using extension cords on permanent pool pumps.[2][1]

- The NEC requires at least one 15–20 A, 125 V receptacle between 6 ft and 20 ft from the pool wall to reduce the temptation to run long cords across the yard.[2]

- Guidance for above‑ground pools often says an extension cord should be only a temporary solution until a buried, dedicated circuit and outdoor receptacle or disconnect are installed.[4][1]

- Extension cords around water increase trip hazards and connection points that can get wet if not properly protected, even when the wire gauge is correct.[4]

Extension cords are labeled with American Wire Gauge (AWG). The smaller the number, the thicker the wire and the more current it can safely carry.[9][3]

- 16 AWG: Light‑duty; adequate for low‑amp, short‑term loads, not recommended for pool pumps.[9][3]

- 14 AWG: Medium‑duty; often used for up to 15 A tools but marginal for continuous, long‑run pool pump use.[10][3]

- 12 AWG: Heavy‑duty; common for 20 A circuits and strongly recommended as a minimum for most temporary above‑ground pool pumps.[11][1]

- 10 AWG: Extra‑heavy‑duty; suitable for higher‑amp loads and longer runs where voltage drop would otherwise be excessive.[3][1]

Tables in NEC‑based resources on flexible cords show how allowed ampacity goes up as wire size gets thicker, but they also assume proper outdoor‑rated insulation and connectors.[3]

A safe temporary extension cord for a pool pump must consider both current draw and length because voltage drop increases with distance.[12][9][1]

- Shorter is safer: If 25 ft reaches, do not buy 50 ft; if 50 ft reaches, do not buy 100 ft.[13]

- For many above‑ground pumps using 120 V and under about 15 A, experts often recommend at least a 12 AWG outdoor cord; some even prefer 10 AWG, especially as distance increases.[11][1]

- At runs approaching 75–100 ft, even 12 AWG can show noticeable voltage drop for a high‑amp pump, which is why many pros say that long‑term you should install a properly wired, closer outlet instead.[12][1]

These examples are illustrative only; local codes and an electrician's judgment always take priority.[1][4][2]

- Small above‑ground pool pump, 0.5–0.75 HP, under 10 A, distance 25 ft: A heavy‑duty 12 AWG outdoor cord can be acceptable as a temporary solution if plugged into a GFCI‑protected outlet.[10][11][1]

- Medium above‑ground pump, about 1 HP, around 12–15 A, distance 50 ft: A 12 AWG cord is generally the minimum; many owners upgrade to 10 AWG to reduce voltage drop and heat.[9][1]

- Larger in‑ground style pump, 1.5–2 HP: These are often hard‑wired 230 V units and should not be run on a household extension cord; instead, use a dedicated circuit sized for the motor according to NEC tables.[14][15][5]

Even with the right size extension cord, safety details matter.[16][11][4][2]

- GFCI protection: Pool pump circuits must be GFCI protected; you can use a GFCI breaker, a GFCI receptacle, or a cord set with built‑in GFCI.[11][1][4]

- Weather‑rated components: Use cords marked for outdoor use, with molded plugs and proper strain relief, and keep all connections off the ground and out of standing water.[16][4]

- Protected connections: Use an outdoor cord‑connection cover or “in‑line” protective housing to keep plug joints dry and mechanically supported.[16]

- Grounding: The cord must have a grounding conductor, and the pump should be properly bonded and grounded according to pool codes to minimize shock hazard.[4]

While consumer blogs sometimes normalize running pumps on long cords, electrical and pool codes push you toward permanent wiring.[1][2][3][4]

- NEC Article 680 sets rules for pools, including bonding, grounding, and equipment connections, and it explicitly addresses cord‑and‑plug connected pump motors and the grounding conductor size.[4]

- Code updates now require a 15 or 20 A, 125 V receptacle between 6 ft and 20 ft from the pool wall, largely to eliminate unsafe cord runs from distant outlets.[2]

- Flexible cord ampacity tables show ratings for cord sets, but they are not intended to replace permanent branch‑circuit wiring for fixed pool equipment.[3]

Use this practical checklist if you must use an extension cord temporarily for your pool pump.[13][11][9][1]

1. Read the pump label

- Note voltage (typically 120 V for many above‑grounds), running amps, and horsepower.[5][1]

- Confirm whether it already has a built‑in GFCI on the factory cord.

2. Measure the actual distance

- Measure the straight‑line distance from the outdoor GFCI outlet to your pump location.[13]

- Select the shortest cord that can comfortably reach with some slack, never longer “just in case.”

3. Pick the correct gauge and type

- For many 120 V pumps up to about 15 A and distances around 25–50 ft, use at least a 12 AWG, 3‑wire (hot‑neutral‑ground) outdoor‑rated cord.[11][1]

- For higher current or longer runs, move to 10 AWG and consider whether it is time to install a permanent circuit instead.[12][1]

4. Verify outdoor and GFCI protection

- Ensure the receptacle is GFCI‑protected; if not, use a cord with a built‑in GFCI or have one installed.[11][1][4]

- Use weather‑resistant cord caps and a protective cover where the factory pump cord plugs into the extension.[16][4]

5. Monitor for heat and performance

- During initial operation, feel the extension cord along its length; it should not become hot to the touch.[1][3]

- If the pump seems to struggle at start‑up or runs noisily, you may have voltage drop issues and should stop and consult an electrician.

There is a clear point where an extension cord is no longer the right tool.[2][1][4]

- If your pump runs all season, day after day, it should be served by a dedicated, code‑compliant circuit with properly sized conductors and an outdoor disconnect or receptacle.[1][2]

- If you need more than a relatively short heavy‑duty cord (for example, 100 ft runs to the nearest outlet), investing in a buried line and a new outlet near the pool is safer and often better for pump longevity.[12][1]

- For larger 230 V pumps, extension cords are generally inappropriate; these loads are normally hard‑wired with conductors sized using motor tables and continuous‑duty factors.[15][14][5]

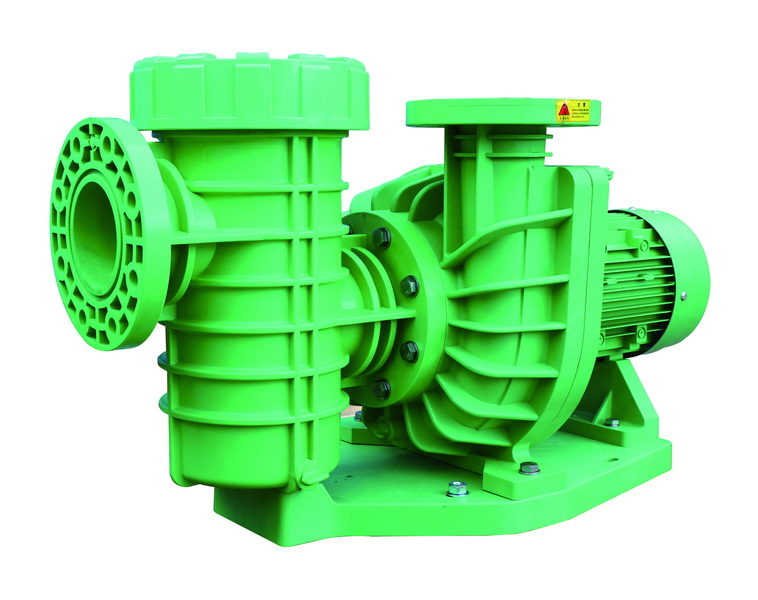

As a professional Chinese factory specializing in high‑end sand filter systems and pool circulation equipment, an OEM partner can deliver not just pumps and filters, but complete, compatible solutions for overseas brands, wholesalers, and system integrators.[7]

- Modern sand filters, DE filters, and cartridge filters paired with efficient pumps can lower overall amp draw while maintaining flow, which in turn reduces stress on wiring and helps meet local code requirements more easily.[17][8][6]

- Smart manufacturing and automated quality control on pumps, filters, LED lights, and accessories ensure consistent performance, making it easier for distributors to publish clear electrical specifications (amps, volts, recommended cord gauge) in their manuals.[8][17][7]

- OEM services can include customized cable lengths, cord caps for specific markets, and integrated GFCI cords where regulations allow, which simplifies safe installation for end users.[5][7][1]

Choosing the right size extension cord for a pool pump is about more than just “will it turn on”; it is about long‑term safety, motor lifespan, and compliance with electrical and pool codes. For many small above‑ground 120 V pumps, a short, heavy‑duty 12 AWG outdoor cord plugged into a GFCI‑protected receptacle can be a reasonable temporary measure, but higher‑amp loads, longer distances, and in‑ground systems quickly push you toward 10 AWG cords or, ideally, a properly installed dedicated circuit. Codes increasingly require outlets near the pool to discourage unsafe cord use, so serious pool owners and professional installers should plan permanent wiring, not rely on long extension cords for seasonal pumps.[9][12][3][11][4][2][1]

No. Light‑duty “indoor” cords or thin 16 AWG cords are not suitable for pool pumps because they are not rated for continuous, high‑amp outdoor use and may overheat or fail in wet environments.[9][3][1]

In some light‑load, short‑distance cases a 14 AWG cord might carry the current, but for continuous‑duty pumps most experts recommend at least 12 AWG, with 10 AWG preferred for longer runs or higher‑amp loads.[10][3][1]

Practically, you should keep extension cords as short as possible—25–50 ft when necessary—and avoid 100 ft runs because voltage drop and trip hazards increase; beyond that, a dedicated circuit and closer receptacle are the better solution.[13][12][1]

Yes. Pool pump circuits must be GFCI‑protected under modern codes, either by GFCI breakers, GFCI receptacles, or a built‑in GFCI on the cord set, to reduce the risk of electric shock near water.[4][2][1]

Codes and professional guidelines treat extension cords as temporary wiring only; a pump that runs for a season or year‑round should have a permanent, code‑compliant connection, not a cord that stays in place indefinitely.[2][1][4]

Choose a heavy‑duty, 3‑wire, outdoor‑rated cord of at least 12 AWG (or 10 AWG for longer runs/high loads), with molded plugs, proper grounding, and, ideally, a weather‑protected connection housing, and plug it into a GFCI‑protected outlet.[16][11][1][4]

[1](https://diy.inyopools.com/article/what-are-the-electricity-requirements-for-above-ground-pools/)

[2](https://www.electricallicenserenewal.com/Electrical-Continuing-Education-Courses/NEC-Content.php?sectionID=170.0)

[3](https://www.mikeholt.com/newsletters.php?action=display&letterID=2168)

[4](https://windsorlocksct.org/wp-content/uploads/2020/09/Swimming_Pools_and_Spas_2014NEC.pdf)

[5](https://blog.royalswimmingpools.com/blog/what-horse-power-pump-should-i-get-for-my-pool)

[6](https://poolpartstogo.com/blogs/articles/what-size-pump-do-i-need-for-my-pool)

[7](https://hayward.com/products/pool-pumps.html)

[8](https://www.poolzoom.com/15-hp-vs-2-hp-pool-pump-which-one-is-right-for-your-pool.html)

[9](https://www.youtube.com/watch?v=9AkB6lsQEjc)

[10](https://forum.allaboutcircuits.com/threads/pool-pump-and-extension-cord-safety.169461/)

[11](https://www.reddit.com/r/AskElectricians/comments/1jicuia/extension_cord_for_pool_pump_please_tell_me_i_can/)

[12](https://www.facebook.com/groups/637529959937311/posts/2578914145798873/)

[13](https://www.facebook.com/groups/637529959937311/posts/2270150843341873/)

[14](https://www.reddit.com/r/AskElectricians/comments/1533020/what_size_circuit_breaker_and_wires_do_i_need_for/)

[15](https://www.garagejournal.com/forum/threads/above-ground-swimming-pool-wire-size-question.481339/)

[16](https://twistandseal.com/products/twist-and-seal-pool-safety-pack-poolside-extension-cord-connection-protection)

[17](https://lesliespool.com/blog/pool-pump-sizing-101.html)

[18](https://www.reddit.com/r/pools/comments/1o5lkza/how_can_i_tell_how_many_horsepower_my_pool_pump/)

[19](https://forums.mikeholt.com/threads/pool-pumps-and-garage-door-openers-nec-2020-load-calculation.2567670/)

[20](https://www.inyopools.com/HowToPage/how_to_size_a_pool_pump_for_your_in_ground_pool_.aspx?CommentPage=1)

Learn how to assemble an above ground pool ladder step by step, from sorting parts and anchoring the frame to key safety checks, maintenance tips, and FAQs to keep pool entry secure and comfortable for every swimmer.<br />

Learn how to anchor a smart pool ladder safely and securely. This step‑by‑step guide covers anchor types, tools, concrete and deck installations, ballast tips, safety checks, and FAQs to keep your pool access stable and compliant.<br />

Learn how to adjust a pool ladder safely and correctly, from measuring pool height and setting leg length to anchoring, stabilizing, and protecting your liner. Includes safety tips, maintenance advice, and answers to common pool ladder questions.<br />

Learn how to add a step to your pool ladder safely and easily. This detailed guide covers choosing compatible steps, tools, installation steps, safety checks, and maintenance, plus ideas for photos and videos to enhance your pool DIY content.<br />

This article explains how much a 51 in pool ladder typically costs, what really drives the price, and which safety and design features matter most. It also shows how professional Chinese OEM factories help brands create durable, high‑capacity ladders that match complete pool systems.<br />

Wondering how much it costs to powder coat a pool ladder? Learn typical price ranges, key cost factors, DIY vs pro considerations, and when recoating beats replacing. Discover how a durable powder‑coated finish can protect your ladder and transform your pool's style.<br />

This in‑depth guide explains how much weight an average pool ladder can hold, typical capacity ranges, key safety standards, and how to choose the right ladder for your pool, with tips on installation, maintenance, and OEM‑ready integrated pool equipment solutions.

Learn how to ground an inground pool ladder safely and correctly by bonding ladder cups into the equipotential grid. This in‑depth guide covers code basics, step‑by‑step bonding, visuals, OEM equipment options, and answers to common electrical safety questions.<br />

Learn how to secure a plastic pool ladder on a concrete patio using the right anchors, flanges, and non‑slip supports. This detailed guide covers tools, drilling, safety, visuals, OEM options, and maintenance for a stable, professional ladder installation.<br />

This guide explains how to get rust off a pool ladder using baking soda, natural acids, and pool‑safe rust removers, plus rinsing, drying, and protecting the metal. It also covers prevention, safety checks, and when to replace the ladder for reliable long‑term use.

Learn practical ways to weigh down an above ground pool ladder using water or sand chambers, sandbags, PVC or concrete anchors, and protective pads. Discover safety tips, visual ideas, and OEM‑grade solutions for stable, liner‑safe ladder installations.<br />

Discover practical, creative ways to reuse an above ground pool ladder for storage, gardening, kids' play, décor, and pool equipment organization. Learn safety checks, DIY tips, visuals to add, and answers to common questions.<br />

Learn how to keep your pool ladder from floating with clear, practical methods: remove trapped air, fill internal sand or water chambers, add safe external weights, protect vinyl liners, and anchor ladders securely for safer everyday swimming.<br />

This in‑depth guide answers “does Dollar General have pool ladder” and explains what pool items Dollar General does sell, where to buy safe pool ladders, and how OEM pool equipment manufacturers support global brands and wholesalers.<br />

This in‑depth guide explains why you should use a mat under your pool ladder, how it protects vinyl liners, improves safety, and extends pool life, with tips on installation, alternatives, durability, and OEM/custom ladder pad options for brands and wholesalers.<br />

Learn how to cover a pool pump safely and attractively. This guide explains ventilation rules, DIY wall and box designs, material choices, landscaping ideas, and OEM options so your pump stays protected, quiet, and easy to service.<br /> <br />

Learn what size extension cord you really need for a pool pump. Understand amp draw, wire gauge, distance, voltage drop, and safety codes, plus when to stop using cords and install a dedicated GFCI circuit. Ideal for above‑ground and in‑ground pool owners and OEM partners.<br />

Learn how to test a pool pump motor safely and accurately. This step‑by‑step guide covers safety, mechanical checks, multimeter voltage and winding tests, capacitor diagnosis, and when to repair, replace, or upgrade to a more efficient pump.<br /> <br />

Discover how much a pool pump really costs, from basic single‑speed units to smart variable‑speed systems. Learn typical price ranges, installation fees, key cost factors, and how energy savings can make premium pumps the better long‑term investment.<br />

Struggling with a pool pump that will not prime? This in‑depth guide explains the most common causes, step‑by‑step priming methods, how to find suction‑side air leaks, and when to upgrade pumps and filters for reliable circulation.<br />