Views: 222 Author: Tina Publish Time: 2025-09-18 Origin: Site

Content Menu

● Calculating Your Pool's Volume

● Additional Factors Influencing Pump Size

● Pump Sizing Chart for Typical Pools

● Choosing the Right Pump Type

● Installation Tips for Optimal Pump Performance

● Maintenance and Troubleshooting

● Frequently Asked Questions (FAQs)

>> 1. How do I know if my pool pump is too big or too small?

>> 2. Can I use a variable-speed pump with all types of pool filters?

>> 3. How often should I run my pool pump?

>> 4. What pipe size is best for my pool pump?

>> 5. What maintenance does a pool pump require?

Choosing the right size pool pump is essential for maintaining clean, clear, and healthy pool water. A pump that is too small will struggle to circulate the water effectively, while an oversized pump wastes energy and may cause unnecessary wear. This detailed guide explains how to determine what size pool pump you need, considering factors such as pool volume, plumbing size, desired turnover rate, and pump efficiency to ensure optimal performance and cost-effectiveness.

A pool pump circulates water through the filtration system, removing debris and distributing chemicals evenly throughout the pool. It typically consists of a motor, impeller, and housing, which filters water before sending it back to the pool.

- Flow Rate (GPM): Gallons per minute, indicating how much water the pump can move.

- Horsepower (HP): Motor strength, affecting flow velocity and energy consumption.

- Turnover Rate: The time needed to circulate the entire pool volume once, usually recommended between 6 to 8 hours for clean water.

A properly sized pump balances energy efficiency with adequate water movement to maximize filter performance and prolong equipment life.

Before selecting a pump, it's crucial to calculate the exact volume of your pool. This volume dictates how much water the pump must circulate to maintain cleanliness.

Common Volume Formulas:

- Rectangular pool:

Volume (gallons)=Length (ft)×Width (ft)×Average Depth (ft)×7.5

- Circular pool:

Volume (gallons)=π×Radius2×Average Depth×7.5

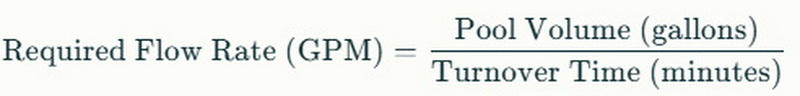

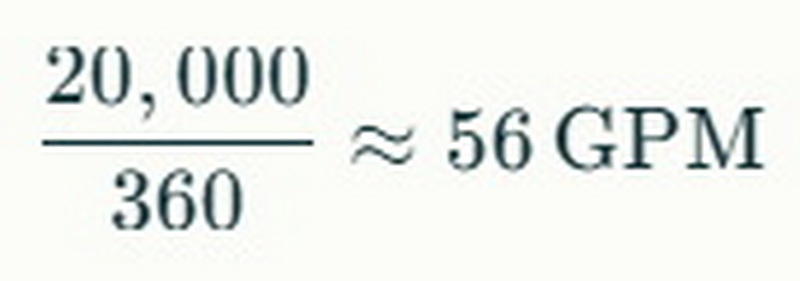

Once the volume is known, calculate the flow rate needed using the desired turnover time. The turnover time defines how quickly you want to circulate all pool water through the filter.

For example, a 20,000-gallon pool with a 6-hour turnover time requires:

This value tells you how many gallons your pump should move each minute to achieve the turnover goal.

Beyond volume and turnover rate, several practical factors impact pump selection:

- Pipe Diameter and Length: Smaller or longer pipes create more resistance (head loss), reducing flow rate. Oversized pumps can't compensate for restrictive plumbing.

- Pool Features: Water features like waterfalls or spa jets require extra flow capacity to operate without affecting filtration.

- Pump Efficiency and Type: More efficient motors consume less energy for the same flow. Variable-speed pumps allow better control and energy savings over single-speed models.

- Filter Compatibility: Different filters (sand, DE, cartridge) work optimally within certain flow ranges. Excessive flow may damage or shorten filter life.

| Pool Volume (gallons) | Turnover Time (hrs) | Required Flow Rate (GPM) | Recommended Pump HP |

|---|---|---|---|

| 10,000 | 6 | 28 | 0.5 - 1.0 |

| 20,000 | 6 | 56 | 1.5 - 2.0 |

| 30,000 | 6 | 83 | 2.0 - 3.0 |

| 40,000 | 6 | 111 | 3.0 - 4.0 |

These recommendations can vary slightly depending on plumbing size and additional features.

Pool pumps mainly come in three types, each with distinct advantages:

- Single-Speed Pumps: Operate at full power continuously. They are less energy-efficient and may cost more over time in electricity.

- Two-Speed Pumps: Have settings for high and low speed. Running at low speed saves energy while maintaining adequate circulation.

- Variable-Speed Pumps: Offer precise speed control, optimizing performance and cutting energy costs dramatically. They also run quieter and increase equipment lifespan.

Variable-speed pumps, while more expensive upfront, often prove cost-effective due to energy savings and better pool water management.

Proper installation ensures the pump operates efficiently and minimizes wear:

- Match your pump's capacity with pipe size; avoid excessive pipe restrictions.

- Install the pump as close as possible to the water source to minimize suction lift.

- Use a pump basket to trap debris before filtration.

- Ensure exhaust vents and motors have adequate ventilation.

- Employ variable-speed pumps with programmable timers to optimize run times based on pool usage.

Maintaining your pump maximizes lifespan and pool health:

- Clean the pump basket regularly to avoid clogs.

- Inspect seals and gaskets to prevent leaks.

- Monitor pressure gauges; abnormal pressure suggests filter issues.

- Listen for unusual noises indicating motor or bearing problems.

- Test water flow periodically and adjust pump settings as needed.

Choosing the right size pool pump requires careful calculation of your pool's volume, consideration of turnover rate, and understanding plumbing constraints. Selecting the appropriate pump horsepower and speed options ensures efficient water circulation, energy savings, and longer equipment life. Variable-speed pumps, though premium priced, typically offer the best balance of cost-efficiency and performance. Coupled with proper installation and regular maintenance, the right pump will keep your pool water sparkling clean and inviting throughout the swimming season.

A pump too large causes excessive pressure, wastes energy, and may damage pipes or filters. A pump too small results in poor circulation and ineffective filtration, leading to cloudy water.

Yes. Variable-speed pumps are compatible with sand, diatomaceous earth (DE), and cartridge filters, offering energy savings and flexible flow rates.

It's recommended to run the pump long enough to circulate the entire pool volume once daily, usually 6 to 8 hours depending on pool size and climate.

Most residential pools use 1.5 to 2-inch pipes. Larger pools or pumps with higher flow rates may require 2.5-inch pipes or larger to reduce friction losses.

Regular cleaning of the pump basket and filter, inspection of seals and motor, checking for unusual noises, and ensuring proper water chemistry to prevent corrosion.

This guide explains how to safely increase pressure on a pool pump by restoring healthy water flow. Learn to diagnose low pressure, clean baskets and filters, fix air leaks, adjust valves and pump speed, and know when equipment upgrades or gauge replacement are necessary.<br />

This in‑depth guide explains how much it costs to replace a pool pump, covering typical price ranges, pump types, labor charges, and long‑term energy savings. Learn when to repair vs replace, DIY vs professional options, and how OEM pump and filter solutions can reduce lifetime ownership cost.<br />

Learn exactly how long to run a pool pump daily for crystal‑clear, safe water and lower energy bills. This in‑depth guide explains turnover, seasonal adjustments, single‑ vs variable‑speed schedules, energy‑saving tips, and practical examples, plus answers to common runtime questions.

This in‑depth guide explains the real reasons your swimming pool pump is not working, from power and priming issues to clogged impellers, dirty filters, and motor failures. Learn step‑by‑step troubleshooting, key maintenance tips, and when to repair or replace your pool pump.

Learn how to remove a pool pump motor safely and efficiently with this step‑by‑step guide. Discover the tools you need, how to disconnect power and plumbing, when to call a pro, and how OEM filter and pump solutions can support overseas pool brands and wholesalers.<br />

This article introduces leading Pool Cleaning Equipment Manufacturers and Suppliers in the UK, outlines their key products, and explains how international brands can combine UK distributors with Chinese OEM factories to build competitive, high‑quality private‑label pool cleaning and filtration lines.

This article outlines the leading Pool Cleaning Equipment Manufacturers and Suppliers in America, explains key product categories such as sand filters, pumps, and robotic cleaners, and shows how importers can combine U.S. brands with Chinese OEM partners to build competitive, high‑margin pool equipment portfolios.<br />

This article introduces the European market for pool equipment and accessories, profiles key Pool Cleaning Equipment Manufacturers and Suppliers, and explores OEM opportunities for Chinese factories producing sand filters, pumps, cleaners and LEDs for European brands and wholesalers.<br />

This article profiles top Pool Filter Valve Manufacturers and Suppliers in Canada, including Praher Plastics, global brands like Hayward and Carvin, and leading distributors. It explains key valve types, buying factors, and how foreign OEM factories can partner with Canadian suppliers for complete pool filtration solutions.<br />

Discover top Pool Filter Valve Manufacturers and Suppliers in Korea, from Korea Filter to SEDA, offering innovative multiport valves, OEM services, and eco-friendly designs for global pools. Explore advancements, certifications, and FAQs in this comprehensive guide to superior filtration solutions.

This article introduces leading Pool Filter Valve Manufacturers and Suppliers in Japan and Asia, covering valve types, key Japanese pool brands, OEM opportunities, and application segments. It explains how advanced engineering, strict quality control, and strong visual marketing help exporters win global pool projects.

This article introduces the main types of Pool Filter Valve Manufacturers and Suppliers serving Russia, including local distributors, industrial filter producers, global brands, and Chinese OEM partners. It explains key selection criteria, product ranges, and OEM opportunities for Russian pool projects.<br />

This article introduces the leading Pool Filter Valve Manufacturers and Suppliers in Australia, explains common valve types and technical features, highlights major distributors and OEM opportunities, and offers practical tips for international buyers sourcing compatible filtration valves and systems.

This article introduces Italy’s leading Pool Filter Valve Manufacturers and Suppliers, detailing their technologies, materials, OEM services, and application scenarios. It explains how Italian valves integrate with sand, DE, and cartridge filters and why global brands choose Italian partners for premium pool filtration solutions.<br />

This article introduces the Portuguese market for pool filtration equipment and highlights how local specialists, European brands, and Chinese OEM Pool Filter Valve Manufacturers and Suppliers cooperate to serve residential and commercial pools, offering multiport valves, filters, pumps, and customized OEM solutions.<br />

This article explains whether you can safely use pool filter sand in an aquarium, covering sand types, preparation, pros and cons, plant and fish compatibility, maintenance tips, and alternatives. It helps hobbyists choose and manage substrate using pool-grade filtration media.

This article explains when to backwash a pool filter using pressure readings, water clarity and flow as guides. It covers sand and DE filter schedules, backwash steps, common mistakes, troubleshooting cloudy water, and how OEM sand filter systems can simplify maintenance for global pool owners.<br />

This article explains what pool filter balls are, how they work, and why they are an increasingly popular alternative to sand in residential pool filters. It covers benefits, installation, maintenance, compatibility, and OEM opportunities for brands seeking high‑performance filtration solutions.<br />

This article explains how often to change a pool filter cartridge, covering typical 1–3 year lifespans, signs of wear, and factors like usage, climate, and maintenance. It shows how cleaning frequency, pressure readings, and water clarity guide replacement and highlights the value of OEM cartridge solutions.

This article explains how often to change a pool filter cartridge, covering typical 1–3 year lifespans, factors that affect replacement timing, and clear signs of wear. It outlines cleaning versus replacement, residential vs commercial schedules, and highlights OEM cartridge solutions for complete pool filtration systems.<br />