Content Menu

● Understanding Pool Pump Voltage (115V vs 230V)

● Tools, Materials, and Code Requirements

● Grounding and Bonding Basics

● Step-by-Step: How to Wire a Pool Pump

>> Step 1: Plan the Circuit and Location

>> Step 2: Turn Off Power and Route Conduit

>> Step 3: Install GFCI Breaker or GFCI Receptacle

>> Step 4: Make Electrical Connections at the Pump

>> Step 5: Connect Bonding Conductor to Pump and Pool

>> Step 6: Install and Wire Timers or Controllers (Optional)

>> Step 7: Final Inspection and Testing

● Common Wiring Mistakes to Avoid

● Integrating OEM Pumps and Filtration Systems

>> 1. Can I wire a pool pump myself?

>> 2. How do I know if my pool pump is 115V or 230V?

>> 3. Why does a pool pump need a GFCI breaker?

>> 4. What is the difference between grounding and bonding on a pool pump?

>> 5. Do I need a timer or automation system for my pool pump?

>> 6. How close can the electrical outlet or disconnect be to the pool?

>> 7. What should an OEM buyer specify when ordering pumps for different markets?

Wiring a pool pump is a critical safety task that must follow local electrical codes, correct voltage, and proper grounding and bonding to protect users from electric shock. For anything beyond very basic work, most homeowners should hire a licensed electrician instead of attempting a full DIY installation.[1][2][3]

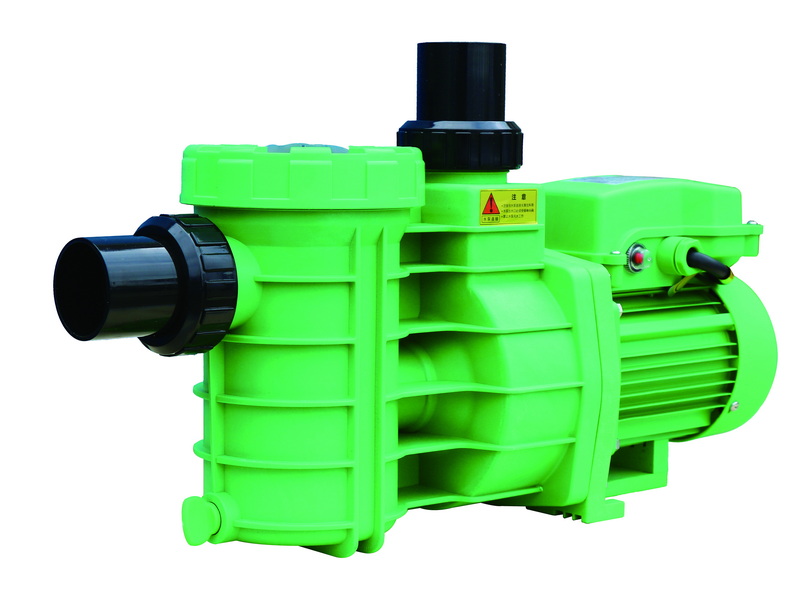

As a professional Chinese factory manufacturing premium pool pumps, sand filters, DE filters, cartridge filters, LED lights, and complete filtration systems, this guide is written to help pool owners, builders, and overseas OEM partners understand the key wiring principles and on-site steps needed to wire a pool pump safely and efficiently. Text, images, and videos should work together so end users can see clearly how to connect power, ground, bonding, and controls at the pad.[4][5][6]

Always treat a pool pump as live electrical equipment around water and start with safety, not wiring. Electrical shock risk is serious; incorrect wiring or missing bonding can create dangerous voltage gradients in and around the pool water.[7][2][8]

Key safety rules before starting:

- Turn off and lock out the breaker feeding the pool pump circuit before handling any wires.[3][1]

- Use a non-contact voltage tester and/or multimeter to confirm power is off at the pump and junction box.[9][6]

- Follow the installation manual for your specific pump model and national/local electrical codes (such as NEC Article 680 in the U.S.).[2][10]

- If you are not fully comfortable with electrical work, hire a qualified electrician or pool professional.[11][3]

Before wiring a pool pump, confirm whether it is designed for 115V, 230V, or dual-voltage operation. Many in-ground pool pumps and higher-horsepower models in places like North America are wired for 230V using a double-pole breaker, while some above-ground and smaller pumps are 115V.[12][9]

Ways to check pump voltage:

- Motor nameplate: The label on the motor usually lists voltage (e.g., “115V only,” “230V only,” or “115/230V”).[9]

- Breaker type: A single-pole breaker often indicates a 115V circuit; a double-pole breaker typically indicates a 230V circuit, although this is not a guarantee.[11][9]

- Wiring pattern: A typical 230V pump uses two hot wires plus ground; a typical 115V pump uses one hot, one neutral, and a ground.[13][9]

A safe pool pump wiring job needs proper tools, wire types, conduit, and protective devices that comply with local code. The exact requirements vary by country and region, but a few elements are almost universal in modern pool installations.[10][1][2]

Common tools and materials:

- Non-contact voltage tester and multimeter.[9]

- Screwdrivers, wire strippers, cable cutters, and appropriate crimp or fork-type connectors.[14]

- Listed outdoor-rated junction boxes, PVC or metal conduit, and fittings suitable for wet locations.[1][3]

- Copper conductors of adequate gauge sized for pump load and circuit length.[13]

- GFCI protection (GFCI breaker or GFCI receptacle) as required by code for pool equipment.[10][1]

- No. 8 AWG (or per code) solid copper bonding wire and listed bonding lugs for pump, pool structure, and metal parts.[7][2]

Grounding and bonding protect swimmers from electric shock by ensuring fault currents have a safe path back to the panel and that all conductive parts around the pool are at nearly the same electrical potential. Improper or missing bonding is a common defect in pool inspections and is strictly regulated by modern electrical codes.[8][2][7][10]

- Grounding: Connects equipment grounds (green or bare copper wire) back to the panel's grounding bus, so if a live conductor contacts the pump housing, the breaker trips quickly.[2][13]

- Bonding: Uses a solid copper bonding conductor (often 8 AWG) to tie together all metallic parts in the pool area, including pump housing, metal pool walls, ladders, rails, and sometimes the reinforcing steel or deck bonding grid.[7][2]

- Water bonding: In many codes, a special water-bonding fitting or device is required to bond the pool water itself through a conductive element in contact with the water.[7]

The general wiring process for a pool pump includes routing the circuit, installing boxes and conduit, making terminations at the pump, and testing the system. The exact method depends on whether you are wiring a new pump, replacing an old unit, or upgrading from 115V to 230V with a new breaker and conductors.[15][3][1]

Before you touch any wires, decide where the pump will sit, how conduit will run, and where the disconnect or timer will be located. Short, direct runs reduce voltage drop, and placing a weatherproof disconnect or timer close to the pump makes service easier.[15][1]

Planning checklist:

- Confirm voltage and amperage from pump nameplate and cross-check with breaker size and wire gauge.[9]

- Choose a solid, level, ventilated base for the pump, high enough to stay dry in rain or splash.[15]

- Ensure required clearances for service, and keep the receptacle or disconnect at the required distance from the pool wall per code.[10][7]

Turn off the main breaker feeding the pool subpanel or the dedicated breaker feeding the pump circuit. Confirm that power is off at the existing pump or junction box using your tester.[1][9]

Then:

- Install conduit from the panel or subpanel to a weatherproof junction box or timer near the pump.[1]

- Continue conduit from the box to the pump's wiring compartment, maintaining proper burial depth for underground runs if required (often 18–24 inches for rigid PVC, per local code).[10][1]

- Pull appropriately sized conductors (hot, neutral if needed, and ground) through the conduit, leaving enough slack at both ends for terminations.[15]

Most pool pump circuits require ground-fault protection to reduce the risk of electric shock. This is often achieved through a GFCI breaker in the panel or a GFCI receptacle (for cord-and-plug-connected pumps) installed at the required distance from the pool.[13][1][10]

- For hardwired pumps, install a listed GFCI breaker sized for the pump load (for example, 20A or 30A, depending on pump specifications).[1][10]

- For some above-ground setups, use a twist-lock GFCI receptacle with an in-line shut-off within the allowed range from the pool wall.[13][7]

Inside the pump's rear or top wiring compartment, there will be a terminal block or wire leads and a grounding lug. Always follow the wiring diagram on the pump motor label because color codes can vary by region and manufacturer.[16][14][9]

For a typical 230V hardwired pump:

- Two hot wires (often black and red in North America) each connect to a “L1” and “L2” terminal.[17][9]

- The equipment grounding conductor (green or bare copper) connects to the green screw or grounding lug on the motor frame.[2][13]

For a typical 115V pump:

- The hot conductor connects to the “Line” or “Hot” terminal, and the neutral (often white) connects to the neutral terminal, plus a ground to the green screw.[16][9]

- Some dual-voltage motors require moving an internal selector or jumper to switch from 115V to 230V; follow the motor diagram precisely.[18][9]

Attach a solid copper bonding conductor (often 8 AWG) to the pump's external bonding lug using a listed connector. The same bonding conductor or bonding grid should also connect to other metallic components like ladder rails, metal pool walls, and any metal within about 5 feet of the pool, as required by code.[8][2][7]

- Run the bonding conductor continuously or use approved splices to form an equipotential bonding ring around the pool area.[7]

- Ensure all clamps, lugs, and fasteners are corrosion-resistant and listed for direct burial where applicable.[2]

Many pool owners use mechanical or digital timers, automation panels, or smart controllers to control pump runtimes. When wiring a timer, ensure that the timer is rated for the pump's voltage and current and installed in a weatherproof enclosure if outdoors.[5][15]

- Line side: Connect incoming hot (and neutral if required) from the breaker or subpanel to the “Line” terminals on the timer.[15]

- Load side: Connect outgoing conductors from the timer to the pump's supply, matching voltage and polarity per the diagram.[15]

- Ground and bond: Maintain ground continuity and bond any metallic timer enclosures if required.[2]

Once all connections are complete, it is vital to inspect and test the installation before running the pump under normal load. A licensed electrician or pool inspector should check that all wiring, bonding, and grounding meet code requirements.[3][10][2]

Checklist before startup:

- All covers, strain reliefs, and conduit fittings are installed and tightened.[1][15]

- Ground and bonding wires are secure, continuous, and properly connected.[7][2]

- GFCI breaker or GFCI outlet tests correctly using the “Test/Reset” buttons.[1]

- Voltage at the pump terminals matches the motor rating within acceptable tolerance.[12][9]

Several recurring mistakes can damage pumps or create safety hazards for swimmers. Avoiding them will extend the life of the pump and help keep the pool compliant with inspection requirements.[6][9][2]

Frequent errors include:

- Misidentifying neutral as a hot conductor or using white wire as a hot without proper re-identification, which can confuse future servicing and be dangerous.[9][13]

- Feeding a 115V-only pump with 230V, risking immediate motor damage or tripping breakers.[12][9]

- Omitting or incorrectly installing bonding conductors, leaving metal parts at different potentials around the pool.[2][7]

- Using non-weatherproof boxes or indoor-rated devices outdoors, causing corrosion or water ingress.[3][1]

For overseas brands, wholesalers, and manufacturers working with an OEM factory, wiring considerations affect how pumps and filtration systems are specified and packaged. Selecting the correct motor voltage, cable length, plug type, and label information for each target market reduces installation errors on site.[11][12]

An experienced OEM supplier can:

- Provide pumps pre-configured for 115V or 230V, with clear wiring labels and diagrams in multiple languages.

- Offer matched sand filters, cartridge filters, valves, and LED lights designed to integrate into local electrical systems, including bonding points and metal components suitable for equipotential bonding.[2]

- Supply branded manuals, QR-linked how-to videos, and panel stickers that help installers follow safe wiring, grounding, and bonding practices.[4][6]

Correctly wiring a pool pump is about much more than simply connecting three wires; it combines proper voltage selection, code-compliant grounding and bonding, GFCI protection, and careful routing of conduit and conductors. When in doubt, homeowners and commercial facilities should rely on licensed electricians and professional pool installers, while OEM pumps and filtration systems should be specified and labeled for the target market to make field wiring safer and more intuitive.[3][2][1]

Many regions allow homeowners to do limited electrical work, but pool equipment falls under strict safety codes because it is electricity near water. Unless you have solid electrical knowledge and understand local regulations, it is safer and often required to use a licensed electrician or qualified pool professional.[11][3][10][2]

Check the motor nameplate on the pump for voltage information such as “115V,” “230V,” or “115/230V.” If the label is unclear, an electrician can verify voltage at the supply wires or at the breaker (single-pole vs double-pole), and testing ensures the pump is wired to the correct voltage.[11][9]

A GFCI device (breaker or outlet) helps detect ground-fault currents and shut the circuit off quickly, reducing the risk of electric shock around the pool. Many modern electrical codes explicitly require GFCI protection for pool pump circuits, especially for outdoor and wet locations.[13][10][1]

Grounding connects the pump's metal parts to the panel's grounding system so that if a fault occurs, the breaker trips. Bonding ties all conductive parts around the pool (pump, metal walls, rails, and often the reinforcing steel and water) together to equalize potential and reduce shock risk from voltage differences.[8][13][7][2]

A timer or automation system is not strictly required, but it helps run the pump for optimal hours per day without manual switching, saving energy and maintaining consistent circulation. Many modern variable-speed pumps integrate with automation controllers, allowing scheduled runtimes and speeds that improve efficiency and user convenience.[6][12][15]

Electrical codes typically specify minimum distances from the pool water to outlets, switches, and disconnects to reduce shock risk, with different rules for GFCI receptacles and twist-lock pump outlets. Because requirements vary by jurisdiction, always confirm current local code or consult a licensed electrician before installing outlets near the pool.[8][10][7][2]

OEM buyers should specify the target voltage and frequency (e.g., 230V/50Hz for Europe, 115/230V/60Hz for North America), cord length and plug type, label language, and any special bonding or ground wiring provisions required by local regulation. Providing these details allows the manufacturer to supply pumps, filters, and LED lights that integrate smoothly into local electrical systems and reduce on-site wiring problems.[12][10]

[1](https://www.thisoldhouse.com/pools/21016222/how-to-wire-an-above-ground-pool-pump)

[2](https://www.nachi.org/grounding-bonding-swimming-pools.htm)

[3](https://parkinelectric.com/essential-steps-for-safe-pool-pump-wiring-installation/)

[4](https://www.youtube.com/watch?v=im9BVObcLBA)

[5](https://www.youtube.com/watch?v=ImhZ0RA0iZY)

[6](https://patopu.com/news/pool-pump-electrical-wiring-a-safety-first-guide/)

[7](https://pacodealliance.com/wp-content/uploads/2023/12/Above-Ground-Pool-Bonding-Requirements_10-23-20.pdf)

[8](https://j2services.us/grounding-and-bonding-requirements-for-pools/)

[9](https://diy.inyopools.com/article/is-my-pool-pump-115v-or-230v/)

[10](https://www.nyeia.com/wp-content/uploads/2019/05/2019_Swimming-pool-NEC17-.pdf)

[11](https://nonstopswim.com/blogs/news/are-pool-pumps-110-or-220-v-what-you-need-to-know-before-plugging-in)

[12](https://poolpartstogo.com/blogs/articles/pool-pump-voltage)

[13](https://www.nespapool.org/Portals/0/08_nj_nec_electrical_code.pdf)

[14](https://www.reddit.com/r/pools/comments/18mbfml/two_questions_about_wiring_a_pump/)

[15](https://poolpartstogo.com/blogs/articles/step-by-step-guide-installing-a-pool-pump-and-ensuring-proper-circulation)

[16](https://www.inyopools.com/HowToPage/how_to_wire_a_pool_pump.aspx?CommentPage=1)

[17](https://www.youtube.com/watch?v=Sh3MQ0nJJeY)

[18](https://www.reddit.com/r/AskElectricians/comments/1m9u3re/pool_pump_wiring/)

[19](https://www.reddit.com/r/swimmingpools/comments/1mjhhyu/do_i_set_pump_for_115_or_230_volts/)

[20](https://www.facebook.com/groups/273395260599363/posts/1431648774774000/)

Learn how to convert a frame pool ladder into a safe, professional deck ladder with proper planning, flanges, and anchors. This step‑by‑step guide covers tools, installation, safety checks, maintenance, and OEM opportunities for pool ladder and filtration system suppliers.

This detailed guide explains how to clean under a Confer pool ladder step by step, remove algae and stains, and keep the ladder and hidden areas safe and spotless. Learn tools, cleaners, shock routines, and ongoing maintenance tips to prevent algae from returning under any pool ladder.<br />

This in‑depth guide explains how to clean a resin pool ladder step by step, remove algae, stains, and scale, and protect the ladder from damage. Learn tools, cleaners, safety tips, and maintenance routines to keep every pool ladder safe, bright, and long‑lasting all season.<br />

This comprehensive guide explains how to clean a pool ladder step by step, remove scale, stains, and rust, and protect it from future damage. Learn tools, routines, seasonal tips, plus content ideas to keep every pool ladder safe, stable, and professional‑looking.<br />

Learn how to clean your aluminum pool ladder step by step, remove stains and oxidation, and protect it from corrosion. Discover easy maintenance tips to keep your pool ladder safe, shiny, and long‑lasting all season.<br />

Learn how to hook up pool filter hoses step by step for sand, cartridge, and DE systems. This detailed guide covers skimmer, pump, and pool filter connections, diagrams, leak‑prevention tips, and FAQs so your pool filter runs smoothly all season.<br />

Learn how to hide your pool filter and pump with smart screens, sheds, landscaping, and multi‑purpose furniture. Discover safety rules, noise‑reduction tricks, and design ideas to keep pool filter equipment quiet, accessible, and invisible in a clean, resort‑style backyard.<br />

Learn how to clean a pool filter pump impeller step by step, restore strong water flow, and protect your pool filter system. Discover warning signs, quick cleaning methods, deep disassembly tips, and preventive maintenance to keep your pool crystal clear and your pump running efficiently.<br />

Learn how to change a Bestway pool filter without losing water. Step‑by‑step methods for cartridge and sand filters, essential tools, safety tips, and maintenance advice to keep your Bestway above‑ground pool clear, efficient, and easy to manage all season.<br />

Learn how to change a Bestway pool filter step by step. This detailed guide covers cartridge and sand pool filter pumps, safety tips, backwash and rinse, maintenance schedules, troubleshooting, and FAQs to keep your above‑ground pool crystal clear all season.<br />

Learn how to backwash a Bestway pool filter step by step, including valve settings, backwash and rinse times, pressure‑gauge tips, and maintenance advice. Keep your sand pool filter efficient, protect your pump, and enjoy consistently clear, healthy pool water with simple, repeatable routines.<br />

Learn how to add diatomaceous earth to a pool filter step by step, including safety tips, DE dose calculations, backwashing, DE mixing and skimmer charging, pressure‑gauge checks, and maintenance advice for crystal‑clear pool water and long‑lasting DE pool filter performance.<br />

This in‑depth guide explains how often to clean a Pentair pool filter, with specific schedules for sand, cartridge, and DE systems, pressure‑based rules, seasonal adjustments, troubleshooting signs, and OEM‑level pool filter solutions for international brands and professional buyers.<br />

Learn how often to change an Intex pool filter, how to clean cartridge, sand, and DE filters, and how to keep above-ground pool water crystal clear with simple, effective maintenance habits.<br />

This in‑depth guide explains how often to run a pool filter for clear, healthy water. Learn ideal daily runtime for sand, cartridge, and DE pool filters, how turnover works, seasonal adjustments, energy‑saving tips, and OEM pool filter solutions for professional buyers.<br />

Learn how to safely reset a pool pump step by step, from basic power‑cycling and priming to keypad and factory resets for variable‑speed pool pumps. Avoid damage, restore circulation fast, and know when to call a professional.<br />

A pool pump is the heart of any swimming pool, circulating water through filters, heaters, and sanitizers to keep it clean, clear, and safe. Learn what a pool pump does, how it works, how long to run it, and how to choose efficient OEM pool pump solutions for residential and commercial pools.<br />

Learn how to hook up a swimming pool pump the right way with this 2,000‑plus word step‑by‑step guide. Discover planning tips, plumbing and wiring basics, priming advice, troubleshooting ideas, and essential pool pump FAQs for cleaner, clearer pool water.<br /> <p> </p> , and maintain a pool pump so your pool water st

This in‑depth 2026 guide explains how much for pool pump, covering typical prices by type, pool size, and brand, plus installation, repair, and energy costs, and OEM options for brands, wholesalers, and manufacturers seeking efficient, high‑value pool pump solutions.<br />

This detailed guide shows how to hide Pool pump equipment with fences, screens, landscaping, benches and rock features while preserving ventilation, safety and easy maintenance, so your Pool pump stays quiet, discreet and reliable.<br />