Views: 222 Author: Tina Publish Time: 2026-01-21 Origin: Site

Content Menu

● What an Above Ground Pool Pump Does

● Safety First Before Installing a Pool Pump

● Tools and Materials You Will Need

● Choosing the Best Location for the Pool Pump

● Understanding Above Ground Pool Plumbing Layout

● Electrical Requirements for an Above Ground Pool Pump

● Step‑by‑Step: How to Install Pool Pump Above Ground

>> 1. Prepare the Site and Base

>> 3. Connect the Suction Line From Skimmer to Pool Pump

>> 4. Connect the Discharge Line From Pool Pump to Filter

>> 5. Glue and Secure All Plumbing

● Priming the Above Ground Pool Pump

● Testing and Fine‑Tuning the System

● Wiring and Bonding Tips for Pool Pump Safety

● Routine Maintenance for an Above Ground Pool Pump

● Seasonal Care: Opening, Peak Season, and Winterizing

● Troubleshooting Common Above Ground Pool Pump Problems

● Energy‑Saving Tips for Your Pool Pump

● Using Visual Resources for Extra Confidence

● FAQ About Above Ground Pool Pump Installation

>> 1) How far can my above ground pool pump be from the pool?

>> 2) Do I need a professional electrician to wire my pool pump?

>> 3) Why does my above ground pool pump lose prime?

>> 4) How long should I run my above ground pool pump each day?

>> 5) Can I upgrade to a variable‑speed above ground pool pump?

Installing an above ground pool pump correctly is one of the most important steps in keeping your pool water clear, safe, and comfortable for swimmers. A properly installed pool pump protects the rest of your equipment, extends the life of your filter, and helps you avoid costly repairs. This complete guide shows you exactly how to install, wire, prime, test, and maintain an above ground pool pump, even if it is your first time working with pool equipment.

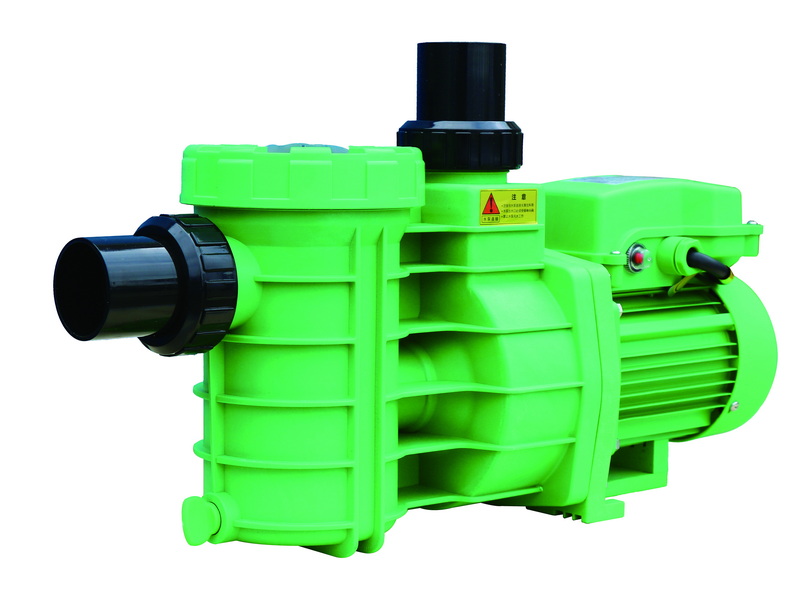

An above ground pool pump is the heart of the circulation system. It pulls water from the pool through the skimmer and main suction lines, pushes it through the filter, and sends cleaner water back into the pool. Without a correctly working pool pump, debris, fine particles, and algae quickly build up.

The pool pump also helps distribute pool chemicals evenly. When the pump moves water properly, chlorine, pH adjusters, and other treatments spread throughout the pool instead of staying in one area. A well-sized and correctly installed pool pump makes it easier to maintain balanced water and reduces the need for emergency shock treatments.

Before you touch any part of the pool pump installation, think about safety. You are working around water, electricity, and pressurized plumbing, which can be dangerous if handled incorrectly.

Always turn off power at the main breaker or disconnect before working on wiring or opening the pool pump housing. Use a non‑contact voltage tester to make sure the circuit is truly off. Follow local electrical and building codes, and if you are not experienced with electrical work, hire a licensed electrician to handle wiring, GFCI protection, and bonding for the pool pump. Never bypass safety devices to make a pool pump run.

Preparing the right tools and materials ahead of time makes the pool pump installation smoother and faster. You do not want to stop halfway through because a key fitting or tool is missing.

Common tools for installing an above ground pool pump include an adjustable wrench, flat and Phillips screwdrivers, PVC cutter or saw, pliers, and a tape measure. For the plumbing, you may need PVC primer and glue, Teflon tape (for threaded fittings), hose clamps, and union fittings. For the base, use paver stones, a pre‑made equipment pad, or a small concrete slab to support the pool pump.

On the electrical side, you may need a weatherproof outdoor receptacle, in‑use cover, conduit, and, in some cases, a GFCI breaker or GFCI receptacle on a dedicated circuit. Make sure all components are rated for outdoor use in damp or wet locations. Having everything ready before you set the pool pump in place reduces the chance of mistakes and rework.

Location affects how well your pool pump can move water and how easy it will be to service in the future. A poor location can cause priming problems, increased noise, and unnecessary wear on the pool pump motor.

Choose a firm, level, and stable surface for the pump near the pool and filter. Placing the pool pump closer to the pool reduces the length of the suction and return lines, which lowers friction loss and makes it easier for the pump to maintain strong flow. Whenever possible, position the pool pump slightly below the level of the pool water so gravity helps water flow into the pump for easier priming.

Leave enough space around the pool pump for ventilation and maintenance. The motor needs airflow to stay cool, and you should be able to easily remove the lid, clean the basket, and disconnect unions. Avoid placing the pool pump in low spots where rainwater collects, and keep it away from mulch or dirt that could wash into the equipment area.

Before connecting anything, it helps to understand the basic flow path. Water leaves the pool through the skimmer and any suction ports, travels to the pool pump, passes through the filter, and then returns to the pool through the return fitting(s).

On the pool pump itself, the front or side port is usually the suction inlet (connected to the skimmer line), and the top or opposite port is the discharge outlet (connected to the filter inlet). The filter outlet then connects to the pool return. Many systems also include valves on the suction and return lines so you can isolate the pool pump for service without draining the entire pool.

Knowing this layout keeps you from accidentally reversing connections. If the pool pump is plumbed backwards, it will not move water correctly and can damage the pump or filter.

Most above ground pool pumps for residential pools are designed for 115‑volt circuits and come with a factory cord and plug. However, even plug‑in pool pumps must follow strict electrical safety rules.

The outlet supplying the pool pump should be a grounded, weatherproof receptacle with an in‑use cover, mounted the correct distance from the pool according to local codes. The pool pump must be protected by a GFCI device to reduce the risk of electric shock. The pool pump and other metal components around the pool should be bonded together with an approved bonding wire to equalize electrical potential.

If the pool pump is hard‑wired instead of plugged in, the wiring should be run in appropriate conduit at the correct burial depth, with a disconnect or switch as required by code. This is usually work for a licensed electrician. Never run extension cords to power a pool pump, as they are unsafe, often undersized, and usually prohibited by code.

Start by preparing the foundation where the pool pump will sit. A stable base reduces vibration and noise and keeps the pool pump level.

Level a pad using compacted gravel, paver stones, or a small concrete slab. Place the equipment pad near the pool wall where the skimmer and return fittings are located. The pool pump should sit on this pad so that the motor is dry and elevated above any runoff.

Set the pool pump on the base with the suction port facing the pool's skimmer connection and the discharge port aligned with the filter inlet. Make sure the pool pump sits solidly with no rocking.

Check that the pool pump is level front‑to‑back and side‑to‑side. A level pump helps the motor bearings wear evenly and makes it easier to keep the pump basket full of water. Leave enough room to remove the lid and basket and to reach the drain plugs at the bottom of the pool pump housing.

The suction line is the path from the pool to the pump. For an above ground pool, this is often a flexible hose or PVC line coming from the bottom of the skimmer.

Attach the hose or pipe from the skimmer outlet to the suction inlet of the pool pump. Use the correct adapter fittings for your model. Wrap threaded connections with Teflon tape and tighten them snugly but do not over‑tighten and crack the housing. If you are using flexible hose, secure it with stainless steel clamps.

An airtight suction line is essential. Even a small air leak on the suction side can make the pool pump lose prime and run dry. Double‑check every clamp, threaded joint, and union for a snug fit as you go.

Next, connect the pool pump outlet to the filter inlet. This line carries water under pressure from the pool pump into your sand filter, cartridge filter, or DE filter.

Use either rigid PVC pipe or flexible hose that is rated for pool use. Position union fittings near the pool pump and the filter so you can easily disconnect the pump for service or winter storage. Follow the flow direction arrows on the filter housing to ensure that water from the pool pump enters the correct port.

Avoid sharp bends and unnecessary fittings that create friction and reduce flow. Keep the plumbing run as short and direct as possible, while still leaving space for valves and unions.

Once the plumbing layout is confirmed, glue and secure all permanent connections.

Dry‑fit each section of pipe and fitting to confirm alignment and length. Mark the joints with a pencil so you can line them up again after gluing. Apply PVC primer (if required by your glue) and then PVC cement to both the pipe end and the fitting socket. Insert the pipe, twist slightly, and hold for a few seconds until it sets.

Allow the glue to cure according to the manufacturer's instructions before running the pool pump. Rushing this step can cause leaks later. Recheck all hose clamps and unions after the glue has cured.

Priming means filling the pool pump and suction line with water so the impeller can create suction. Even above ground pool pumps that are self‑priming often need help the first time.

Make sure the pool water level is at least halfway up the skimmer opening. Open all valves on the suction and return lines so water can flow freely. Remove the pool pump lid, take out the strainer basket, and clear any debris.

Fill the pump housing and basket area with water from a hose until it is completely full. Replace the basket if you removed it, then reinstall the lid carefully, ensuring the o‑ring is clean and seated correctly. A damaged or dry o‑ring can draw air and cause priming problems.

Turn on the pool pump and watch the clear lid. The pump should start pulling water, push air out of the lines, and then run with a solid column of water. You may see air bubbles coming out of the return jets in the pool at first; these should decrease as the pump finishes priming. If the pool pump does not catch prime within a minute or so, shut it off, refill the housing, and check for air leaks on the suction side.

Once the pool pump is running and primed, it is time to test the system and make adjustments.

Check all fittings, unions, and hose connections for drips or sprays. Even tiny leaks can become bigger over time, and suction leaks can make the pool pump lose prime. Tighten clamps, reseal threaded joints, or re‑glue fittings if necessary.

Next, look at the pressure gauge on your filter. Each filter has a normal operating pressure range. If the pressure is much higher than normal, there may be a blockage or a dirty filter. If the pressure is very low, there may be an air leak or a flow restriction on the suction side. Adjust any valves to balance the suction between the skimmer and other ports so the pool pump runs smoothly without cavitation or loud noises.

Safe wiring and bonding are just as important as proper plumbing. A clean installation keeps the pool pump reliable and reduces electrical hazards.

For plug‑in above ground pool pumps, plug only into a properly installed GFCI‑protected receptacle. Make sure the receptacle box has an in‑use cover so the plug and connection stay dry while the pool pump is operating. Route the cord neatly, away from walkways and sharp edges, and never use an undersized extension cord.

Bonding ties together all metal parts in and around the pool, including the pool pump motor, ladder, metal frame, and any other conductive components. This equalizes voltage and reduces the potential for shock. Use the bonding lug on the pool pump motor and follow local codes for wire size and connection methods. If you are unsure how to do this safely, involve a qualified electrician.

Regular maintenance keeps your pool pump efficient and prevents unexpected breakdowns. Think of it as routine care for the heart of your pool system.

Clean the strainer basket regularly, especially during peak season when leaves and debris are common. A clogged basket makes the pool pump work harder and reduces water flow. While cleaning the basket, inspect the lid o‑ring and sealing surfaces; replace worn or cracked o‑rings and use a silicone‑based lubricant to keep them flexible.

Check around the pool pump periodically for signs of leaks, rust, or overheating. Listen for unusual noises such as grinding, squealing, or loud humming, which may indicate worn bearings or an issue inside the pump housing. If the pool pump runs very hot or repeatedly trips a breaker, stop using it and diagnose the cause before continuing.

Pool pump maintenance changes with the seasons. Planning this care keeps your above ground pool ready when you need it and protects your pump when you do not.

At the start of the season, inspect the pool pump for cracks, loose fittings, or damage from storage. Reinstall drain plugs that were removed in winter, reconnect unions and hoses, and ensure that the motor spins freely. Prime the pump carefully and check for proper flow before adding a full load of swimmers.

During peak summer use, clean baskets more frequently and monitor the filter pressure. Heavy swimmer loads and increased debris require more frequent circulation. Adjust run time so the pool pump turns the entire pool volume at least once per day, often 8 to 12 hours depending on pool size and pump flow.

At the end of the season in colder climates, winterize the pool pump. Shut off power, disconnect unions or hoses, and drain all water from the pump housing using the drain plugs. Store the pool pump in a dry, protected location if possible, or cover it to shield it from snow and ice. Remove and store small parts like lids and o‑rings in a labeled bag so they are easy to find next spring.

Even with a correct installation, you may face occasional issues. Knowing how to troubleshoot common pool pump problems can save you time and money.

If the pool pump will not prime or loses prime quickly, check for air leaks on the suction side. Typical points include the pump lid o‑ring, loose unions, cracked hoses, and poorly sealed threaded fittings. Make sure the pool water level is high enough and that the skimmer weir door is not stuck closed.

If the pool pump is running but there is very little flow, the problem may be a clogged basket, a dirty filter, or an obstruction in the plumbing. Clean the strainer basket and backwash or clean the filter. Check for kinks in flexible hoses and verify that all valves are fully open.

If the pool pump is noisy, whining, or grinding, there may be air in the system, cavitation, or failing bearings. Air‑related noises often improve when suction leaks are fixed and the pool pump is fully primed. Bearing‑related noises often require professional repair or replacement of the motor.

Modern pool pumps can be major energy users, but small changes in operation can reduce costs significantly while keeping water clean.

If your system allows, consider upgrading to a variable‑speed pool pump designed for above ground pools. These pumps can run at lower speeds for longer periods, which often uses less electricity than running a single‑speed pump at full power for shorter periods. Even if you use a single‑speed pool pump, running it during off‑peak electricity hours when possible may lower your utility bills.

Keep the filtration system clean so the pool pump does not need to work against unnecessary resistance. Backwash sand filters, clean cartridge filters, and remove debris as recommended by the manufacturer. A clean, well‑maintained system allows your pool pump to run more efficiently at any given speed.

Many pool owners learn best when they can watch each step of a pool pump installation. While this written guide is designed to stand on its own, combining it with visual resources can make the process even easier.

Installing an above ground pool pump does not have to be difficult. By choosing the right location, setting the pool pump on a solid base, making careful suction and return connections, and following safe wiring and bonding practices, you can build a reliable circulation system that keeps your pool water inviting. Priming the pump correctly, checking for leaks, and monitoring filter pressure help you fine‑tune the system after installation. With routine cleaning, seasonal maintenance, and basic troubleshooting skills, your above ground pool pump will deliver clear, comfortable water and efficient performance season after season.

Contact us to get more information!

For best performance, keep the pool pump as close to the pool and filter as practical, typically within a few feet of the equipment area. Longer suction and return lines increase friction and make the pool pump work harder, which can reduce flow and make priming more difficult. If you must place the pump farther away, use larger‑diameter plumbing and gentle bends to reduce resistance.

If your above ground pool pump comes with a cord and plug and you already have a properly installed outdoor GFCI outlet, you may be able to connect it yourself. However, any work involving new wiring, underground conduit, breaker changes, or bonding should be handled by a licensed electrician. Proper wiring and bonding protect your family and ensure your pool pump operates safely and in compliance with local codes.

Most priming problems come from air leaks or low water levels. Check that the pool water is high enough to cover at least half of the skimmer opening and that the skimmer weir moves freely. Inspect the pump lid o‑ring, unions, and suction fittings for cracks or gaps, and tighten or replace them as needed. Make sure all valves on the suction and return lines are fully open when you start the pool pump.

There is no single answer for every pool, but many above ground pool owners aim to circulate at least one full pool volume each day. Depending on the size of your pool and the flow rate of your pool pump, this often means 8 to 12 hours of run time in warm weather. Heavier bather loads, high temperatures, or algae issues may require longer run times until the water returns to a stable, clear condition.

Yes, many manufacturers offer variable‑speed pool pump models sized specifically for above ground pools. Upgrading to a variable‑speed pool pump can lower your energy costs, reduce noise, and give you more control over flow rates. By running the pool pump at lower speeds for longer periods, you can maintain excellent circulation and filtration while using less electricity than a traditional single‑speed unit.

1. https://greatbackyard.com/blogs/news/your-above-ground-pool-pump-installation-priming-and-maintenance

2. https://www.thisoldhouse.com/pools/how-to-wire-an-above-ground-pool-pump

3. https://poolpartstogo.com/blogs/articles/step-by-step-guide-installing-a-pool-pump-and-ensuring-proper-circulation

4. https://www.vevor.com/diy-ideas/vevor-swimming-pool-pump-installation/

5. https://www.thepoolfactory.com/blogs/equipment/how-to-prime-an-above-ground-pool-pump

6. https://poolproductscanada.ca/blogs/news/above-ground-pool-pump

7. https://intheswim.com/blog/pool-pump-maintenance-101.html

8. https://lesliespool.com/blog/pool-pump-troubleshooting-guide.html

9. https://absolute-electric.com/pool-and-hot-tub-electrical-safety-tips-for-the-summer/

10. https://astardfw.com/2025/04/pool-electrical-wiring-safe-and-code-compliant-pool-wiring-services/

This comprehensive guide explains how to set up a pool pump from start to finish, covering planning, plumbing, electrical work, priming, maintenance, optimization, and troubleshooting so your pool pump delivers clean, efficient, and reliable circulation all season.<br />

Learn how to remove the motor from a Pool pump step by step. This guide covers safety, tools, wiring disconnection, opening the wet end, sliding out the motor assembly, inspection, seal replacement, priming, and when to call a professional.<br />

This in‑depth guide explains how to install an above ground pool pump, from siting, plumbing, wiring, and priming to testing, seasonal care, energy savings, and troubleshooting, helping pool owners maintain clear, safe water all season long.<br />

Learn how to hook up an Intex Pool pump step by step. This guide explains tools, hose routing, suction and return fittings, priming, electrical safety, leak checks, daily operation, troubleshooting, and upgrade tips so your above‑ground pool runs clean and efficiently all season.<br />

This article explains how to fix “no flow” problems on a Pool pump, from basic basket and filter checks through priming, valve settings, air‑leak and impeller inspection, to electrical issues, plus maintenance tips, a clear conclusion, and a practical FAQ.<br />

This in‑depth guide explains how to plan, build, and maintain a safe, attractive deck around a Pool Ladder, covering design, framing, ladder mounting, safety features, lighting, and ongoing care, plus practical FAQs for homeowners and professionals.<br />

This comprehensive guide walks through planning, building, and maintaining a DIY wood Pool Ladder, covering safety design, step‑by‑step construction, non‑slip features, stability, seasonal care, and key FAQs so swimmers enjoy stable, comfortable access to above‑ground pools.<br />

Learn how to build a sturdy Pool Ladder with practical planning, material selection, and step‑by‑step construction guidance. Discover safety, installation, and maintenance tips to create a durable, slip‑resistant Pool Ladder that keeps swimmers comfortable and your pool structure protected.<br />

Learn how to build a heavy duty Pool Ladder with strong materials, stable stairs, and non‑slip steps. This in‑depth guide covers planning, construction, installation, and maintenance so your Pool Ladder is safe, durable, and comfortable for every swimmer.<br />

Learn how to block off a swimming pool ladder safely using removable steps, lockable gates, ladder guards, and full barriers. Discover practical methods for both above‑ground and inground pools to improve child safety and meet modern pool safety guidelines.<br />

Learn how to set up a pool filter step by step. This in‑depth guide covers sand, cartridge, and DE systems, safe plumbing, priming, valve settings, run‑time tuning, and OEM‑grade tips so you can achieve clear, healthy pool water from day one.

Learn how to clean a pool filter pump step by step for sand, cartridge, and DE systems. Discover safety checks, pressure‑based cleaning schedules, pro maintenance tips, and common mistakes to avoid so your pump runs efficiently and your pool stays crystal clear.<br /> <br />

Learn how to backwash a Pentair pool filter step by step. This detailed guide explains sand and DE backwash procedures, why cartridge filters are different, key safety and troubleshooting tips, and OEM‑level upgrade ideas for clear, healthy pool water.<br />

This in‑depth guide explains what backwashing a pool filter is, how it works for sand and DE systems, when to do it, detailed step‑by‑step procedures, key safety tips, and OEM upgrade ideas to keep pool water crystal clear.

Learn how to clean an inground pool filter safely and effectively. This step‑by‑step guide covers sand, cartridge, and DE filters, safety and pressure checks, deep‑cleaning methods, maintenance frequency, and pro‑level OEM tips for clear, healthy pool water.<br /> <br />

Discover how long and when to run your pool pump for crystal‑clear water, lower energy bills, and longer‑lasting equipment. Learn ideal daily runtimes, day vs night strategies, seasonal adjustments, and pro tips for pairing smart pumps with high‑performance sand and cartridge filters.

Learn step‑by‑step how to remove a pool pump impeller safely, from power isolation and disassembly to shaft‑holding methods, thread directions, seal replacement, and OEM‑level maintenance tips, supported by clear photos, diagrams, and tutorial videos.<br />

Learn how much a swimming pool pump really costs, from entry‑level single‑speed units to premium variable‑speed and solar systems. Get realistic price ranges, installation and energy cost tips, sizing guidance, and OEM supply insights to choose the most cost‑effective pump for any pool.<br />

Learn what really makes the best swimming pool pump, from correct sizing and variable‑speed efficiency to installation and maintenance. Discover how to match pump, filter, and plumbing for clear water, quiet operation, and lower energy bills.<br />

Learn how to turn on a pool pump manually with clear, step‑by‑step instructions for mechanical timers, variable‑speed controls, and above‑ground systems. Includes priming, safety tips, troubleshooting, and a practical FAQ to help you run your pool circulation with confidence.<br />