Content Menu

● Before You Start – Safety First

● Tools and Materials You Will Need

● Step 1 – Turn Off Power and Drain the System

● Step 2 – Label and Disconnect the Wiring

● Step 3 – Remove Plumbing and Take Out the Old Pump

● Step 4 – Prepare the New Pump for Installation

● Step 5 – Connect the Plumbing

● Step 7 – Prime and Start the New Pump

● Step 8 – Fine‑Tune Operation and Maintenance

● Recommended Visual Content for This Article

>> 1. How long does it take to replace a pool pump?

>> 2. Can I replace a pool pump myself, or do I need a professional?

>> 3. Do I need a variable‑speed pump?

>> 4. How do I know what size pump I need?

>> 5. What should I do if the new pump is running but not priming?

>> 6. How often should I service my pool pump?

How to replace a pool pump safely and correctly involves planning, the right tools, and careful plumbing and wiring work. With good preparation, most pool owners with basic DIY skills can complete the job in a few hours and enjoy better circulation, cleaner water, and lower energy bills.[1][2][3][4]

Replacing an old or noisy pump is one of the most effective upgrades you can make to your pool system. A new, efficient pump improves water clarity, reduces noise, and can significantly cut your energy costs over time.[2][4][7]

Working around water, electricity, and pressurized plumbing requires strict safety precautions. Take time to read your new pump's manual and your pool system documentation before touching any equipment.[1][5]

- Turn off power to the pump at the main breaker, not just at the timer or switch.[3][5]

- Verify power is off with a non‑contact voltage tester or voltmeter before opening any electrical compartment.[3]

- Wear safety glasses, gloves, and closed‑toe shoes while cutting or gluing PVC and handling wiring.[8][5]

- Relieve system pressure using the air‑relief valve on the filter or by opening a drain plug on the pump housing.[6][1]

Having the correct tools ready will make the replacement smoother and reduce the risk of leaks or wiring mistakes.[9][8]

- Basic hand tools: screwdriver set (flathead and Phillips), adjustable wrench, socket wrench set, and pliers.[8][9]

- Pipe tools: PVC cutter or fine‑tooth saw, pipe wrench, and optionally a strap wrench for unions or tight fittings.[10][8][3]

- Electrical tools: non‑contact voltage tester or voltmeter, wire stripper, and insulated screwdriver.[5][3]

- Plumbing materials: PVC pipes and fittings, unions, PVC primer and cement, and Teflon tape for threaded connections.[1][3]

- New pool pump (or pump and motor) correctly sized for your pool, plus any required o‑rings, gaskets, and shaft seal kit.[2][5]

Shutting down the system correctly protects both you and the equipment.[5][6]

1. Turn off the pool pump at the timer or control panel, then shut off the dedicated breaker in the main electrical panel.[5][3]

2. Use a voltage tester at the pump's wiring compartment to ensure no power is present.[3]

3. Open the filter's air‑relief valve to release pressure until the gauge reads zero.[1]

4. Remove the pump lid and drain plugs on the pump housing to let water drain out and minimize spills.[6]

Accurate labeling makes installing the new pump much easier and safer.[5][1]

1. Remove the electrical cover plate on the motor end using a screwdriver.[5]

2. Take a clear photo of the existing wiring configuration so you can match it later.[1]

3. Use tape to label each conductor (for example, “L1,” “L2,” “ground”) and note whether the circuit is 115 V or 230 V as shown on the motor label.[6][1]

4. Loosen the terminal screws and carefully pull the wires out of the motor, then unscrew the conduit fitting and pull the conduit and wires free.[1][5]

If you are uncertain about the electrical configuration, stop here and call a qualified electrician.[6]

Next, separate the old pump from the suction and return plumbing.[3][1]

- If your system has unions on the inlet and outlet, loosen them with a strap wrench or by hand and unscrew the pump from the lines.[10][3]

- If there are no unions, mark and measure where to cut the PVC so you leave enough straight pipe for fittings or new unions on the replacement pump.[13][1]

- Use a PVC cutter or saw to make straight cuts, then remove the old pump and set it aside for proper disposal or recycling.[3][1]

Clean and deburr the pipe ends with a file or utility knife to help ensure strong leak‑free joints.[1]

Correct preparation ensures the new pump matches your plumbing layout and operates efficiently.[2][13]

- Place the new pump on a level, solid surface on the pad and align it with the existing suction and return lines.[13]

- For many inground pools, a variable‑speed pump is recommended because it can reduce energy consumption and noise compared with single‑speed models.[4][2]

- Install new unions on the pump's inlet and outlet if they are not factory‑installed, using Teflon tape on threaded fittings and tightening carefully.[3][1]

- If you replaced just the motor, ensure the new shaft seal and o‑rings from the appropriate seal kit are installed to prevent leaks.[6][5]

Check that the pump is oriented so the motor has adequate ventilation and is protected from standing water.[4]

Now you can glue or tighten the piping to connect the new pump.[3][1]

1. Dry‑fit all PVC pieces between the pump and existing piping to confirm alignment and avoid strain on fittings.[13][1]

2. Mark joints with a marker, then apply PVC primer followed by PVC cement according to the manufacturer's directions.[1]

3. Push fittings fully together with a twisting motion and hold for several seconds to lock them in place.[3]

4. Wipe away excess glue and allow the recommended curing time before pressurizing the system.[4][1]

5. For threaded or union connections, tighten firmly but avoid over‑torquing, which can crack fittings or o‑rings.[8][10]

Wiring must match both the supply voltage and the pump's wiring diagram.[5][1]

- Confirm the voltage selector (if present) on the new motor is set to match your supply (for example, 115 V or 230 V) following the motor label.[1]

- Feed the labeled power wires and ground through the conduit fitting into the motor wiring compartment and secure the conduit.[5]

- Attach each conductor to the proper terminal as shown on the pump's wiring diagram, tightening screws firmly but not excessively.[5][1]

- Connect the ground wire to the green grounding screw and ensure the external bonding wire is clamped securely to the bonding lug on the motor.[1]

- Replace the wiring cover plate and verify there are no exposed conductors.[5]

If you upgraded from a single‑speed to a variable‑speed pump with a digital controller, follow the manufacturer's instructions for any additional low‑voltage control wiring.[2]

Proper priming protects the new motor and avoids running dry.[4][1]

1. Reinstall any drain plugs on the pump housing and ensure the pump lid o‑ring is clean and lubricated.[4]

2. Remove the lid and fill the pump strainer basket with clean water using a garden hose until the housing is nearly full.[1]

3. Reinstall the lid tightly, making sure the o‑ring seats evenly.[4]

4. Open valves on the suction and return lines and open the filter's air‑relief valve.[1]

5. Turn the breaker back on, then start the pump and watch for a steady flow of water within a minute or two.[4][6]

6. When a solid stream of water and pressure appear, close the air‑relief valve on the filter.[1]

Check for leaks around unions, glued joints, and the pump lid and correct them if needed.[4]

A few adjustments will help your new pump last longer and run more efficiently.[15][4]

- If using a variable‑speed model, program lower speeds for everyday filtration and higher speeds only for tasks like vacuuming or running spa jets.[2][4]

- Clean the pump basket regularly and inspect o‑rings, seals, and fittings at the start and end of each pool season.[6][4]

- Listen for unusual noises such as grinding or rattling, which can indicate worn bearings, cavitation, or air leaks in the suction line.[15]

- Keep the equipment area free of debris, leaves, and standing water to prevent corrosion and overheating.[4]

Some situations are better handled by pool technicians or electricians.[16][15]

- You are uncomfortable working with electricity or your breaker panel.[16][5]

- The existing plumbing is complex, cramped, or contains multiple valves and special fittings.[13]

- You see persistent leaks, low pressure, or error codes after installation that you cannot diagnose.[15][16]

Professional help can prevent damage to equipment, reduce downtime, and ensure your installation complies with local codes.[16]

Because pool pump replacement is highly visual, combining photos and videos dramatically improves understanding.[14]

Suggested images throughout the article:

- Safety gear and breaker shut‑off (safety section).[3]

- Tool kit layout (tools section).[8]

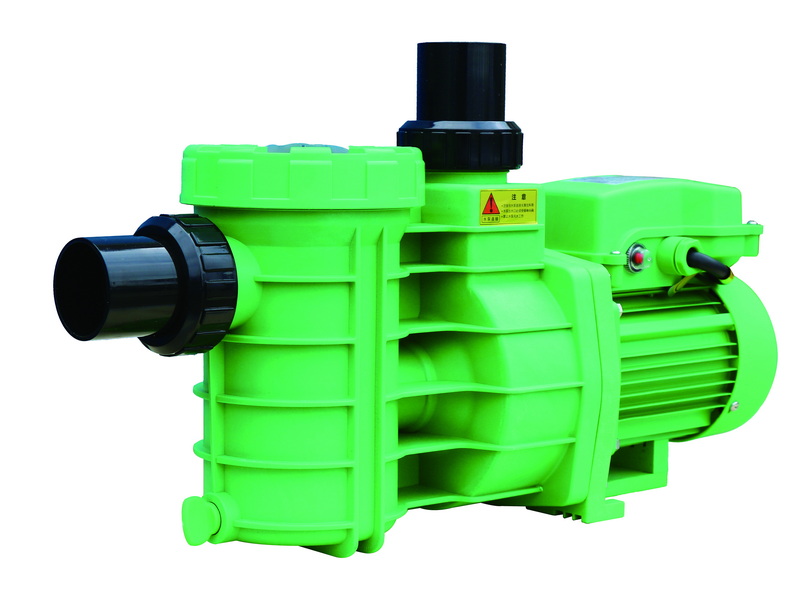

- Old vs new pump on the pad (removal and preparation sections).[13]

- Wiring close‑up before and after (wiring section).[5]

- Priming and running pump (startup section).[4]

Replacing a pool pump is a manageable DIY project when approached methodically, with proper safety steps, tools, and careful attention to plumbing and wiring. By installing a modern, energy‑efficient pump, priming it correctly, and maintaining seals and baskets, you can enjoy quieter operation, clearer water, and lower running costs season after season.[2][3][4][1]

For a straightforward installation with unions already in place, most homeowners can complete the work in about 2–4 hours, including curing time for PVC cement. More complex systems or re‑plumbing can extend the job into a full day, especially if you are working slowly and double‑checking each step.[13][1]

Many pool owners successfully replace pumps themselves if they are comfortable with basic plumbing and can follow safety guidelines closely. If you are unsure about electrical wiring or local code requirements, it is wise to call a licensed electrician or pool professional for at least the wiring portion.[16][6][5][1]

Variable‑speed pumps cost more upfront but often save significant energy by running at lower speeds for daily filtration. They also run quieter and may qualify for utility rebates in some regions, making them a popular upgrade from older single‑speed models.[2][4]

Pump sizing depends on your pool's volume, plumbing layout, filter type, and desired turnover rate. Manufacturers and pool supply sites usually provide sizing charts and calculators that help you match horsepower and flow rate to your specific pool.[13][2]

First, check that the pump basket is full of water, the lid o‑ring is clean and lubricated, and all suction valves are open. If air bubbles persist or the pump never fills, look for air leaks on the suction side (unions, fittings, low water level, or skimmer issues) and correct them before running the pump for extended periods.[15][4][1]

At least once each season, inspect seals, o‑rings, electrical connections, and pump performance, and clean the pump basket regularly. Addressing small leaks, unusual noises, or overheating early can extend the life of the motor and prevent costly failures.[15][6][4]

[1](https://poolpartstogo.com/blogs/articles/how-do-you-replace-a-pool-pump-yourself)

[2](https://www.youtube.com/watch?v=5XSZM-TsThA)

[3](https://www.lowes.com/n/how-to/how-to-replace-a-pool-pump)

[4](https://poolpartstogo.com/blogs/articles/installation-and-maintenance-tips-for-pool-pump)

[5](https://lesliespool.com/blog/how-to-replace-a-pool-pump-motor.html)

[6](https://www.poolmarttx.com/post/guide-to-replace-your-swimming-pool-pump-motor--a-step-by-step-guide)

[7](https://lesliespool.com/blog/when-how-to-replace-pool-equipment.html)

[8](https://www.pumpspluscapecoral.com/post/home-garden-tips-the-top-5-tools-for-diy-pool-pump-repair)

[9](https://diy.inyopools.com/article/top-7-basic-tools-for-pool-diy-ers/)

[10](https://www.reddit.com/r/swimmingpools/comments/17lquy8/what_tool_do_i_use_to_open_a_tight_fitting/)

[11](https://www.youtube.com/shorts/9bbbYSHS0ak)

[12](https://www.youtube.com/watch?v=Fdlik2fca2w)

[13](https://www.homedepot.com/c/ah/how-to-install-a-pool-pump/9ba683603be9fa5395fab901f237ca39)

[14](https://www.youtube.com/watch?v=B-ADIdiWpWA)

[15](https://poolie.com/blog/repair/pool-pump-motor-repair/)

[16](https://naplespool.com/expert-pool-pump-repair-and-replacement/)

[17](https://www.youtube.com/watch?v=6aeIa2oR-m4)

[18](https://www.youtube.com/watch?v=Vmra2FI-tik)

[19](https://www.facebook.com/groups/637529959937311/posts/2233223927034565/)

[20](https://www.reddit.com/r/swimmingpools/comments/udavyn/pump_is_out_replacement_ordered_what_to_do_in_the/)

Learn how to safely increase pressure in your pool pump by restoring proper water flow. This guide covers low‑pressure causes, filter and basket cleaning, air‑leak fixes, valve and gauge checks, and when to upgrade pumps or filters—ideal for pool owners and OEM professionals.<br />

This in‑depth guide explains how long you should run a pool pump each day to keep water clear and costs under control. Learn turnover basics, recommended 8–12 hour runtimes, seasonal and variable speed adjustments, plus how OEM‑grade pumps and filters deliver efficient, reliable performance.<br />

Learn how to remove a pool pump impeller safely step by step, from shutting off power and separating the housing to handling stuck impellers, inspecting seals, and reassembling. Ideal for DIY owners, service techs, and OEM brands supplying pumps and filtration systems worldwide.<br />

Learn how to replace a pool pump step by step, from shutting off power and disconnecting the old unit to plumbing, wiring, priming, and programming a new energy‑efficient pump. Includes safety tips, tool list, recommended images and videos, and answers to common DIY questions.<br />

Learn how to change a pool pump motor safely and correctly, from choosing the right replacement to wiring, seal replacement, and testing. This step‑by‑step guide includes media suggestions, FAQs, and OEM insights from a professional Chinese manufacturer of pumps, filters, and pool accessories.<br />

Learn how often to change sand in a pool filter, with practical guidance on 3–7‑year replacement intervals, key warning signs, and maintenance tips. Discover when cleaning is enough, when a full sand change is needed, and how OEM‑grade sand filters improve long‑term performance.<br />

Learn what type of sand to use in a pool filter, from #20 silica sand to advanced glass and zeolite media. Discover grain size specs, micron ratings, replacement intervals, and OEM sand filter solutions for brands, wholesalers, and professional pool equipment manufacturers.<br />

This article explains why play sand should not be used in a pool filter and details the risks for water quality and equipment. It compares play sand with true pool filter sand, glass, and zeolite media, outlines correct replacement steps, and offers OEM/ODM recommendations for pool systems.<br />

This article explains why play sand should not be used in pool filters, comparing its grain size, shape, and composition with #20 silica pool filter sand. It covers performance risks, approved media options, replacement intervals, and practical guidelines to keep pool water clear and equipment safe.<br />

This in‑depth guide explains how to safely repair a leaking pool filter tank, from identifying the leak source and replacing O‑rings, gaskets, and fittings to deciding when a cracked tank must be replaced. It also covers safety tips, testing, and long‑term OEM upgrade options.<br />

Learn how to stop a pool ladder from floating with practical methods for releasing trapped air, adding internal or external ballast, and anchoring to the deck. This guide explains safety tips, liner protection, circulation, and OEM upgrade ideas, plus image and video suggestions for installers.<br />

Learn how to stabilize a frame pool ladder with practical steps for tightening hardware, leveling bases, adding anti‑slip feet, using ballast and ladder weights, and anchoring to decks or frames, plus maintenance tips, FAQs, and media ideas for safer above‑ground pool access.<br />

Learn how to set up an Intex pool ladder step by step, from assembling A/B legs and locking steps to leveling, stabilizing, and using removable safety steps. This guide adds safety tips, media suggestions, and OEM integration ideas for brands, wholesalers, and pool owners.<br />

Learn how to set up an above ground pool ladder step by step, from choosing the right model and assembling parts to anchoring, stabilizing, and adding safety features. This guide includes media suggestions, maintenance tips, and FAQs to help keep every entry and exit safe and comfortable.<br />

Learn how to set up a pool ladder step by step for both above‑ground and inground pools. This guide covers tools, assembly, anchoring, safety checks, and maintenance, plus suggested images and videos to help you build a stable, secure entry system for your pool.<br />

Discover the leading Pool Cleaning Equipment Manufacturers and Suppliers in Italy, including specialists in filters, pumps, robotics, and water treatment. Learn how Italian brands and Chinese OEM factories can cooperate to deliver cost‑effective, high‑performance pool cleaning solutions for global buyers.<br />

Discover the leading Pool Cleaning Equipment Manufacturers and Suppliers in Portugal, from filtration and pump specialists to eco‑friendly bio‑pool experts. Learn about key companies, OEM opportunities, and how global brands can combine Portuguese technology with efficient OEM production for competitive pool cleaning solutions.<br />

Discover why Spain is a prime destination for Pool Cleaning Equipment Manufacturers and Suppliers, from global leaders like Fluidra/AstralPool to specialist pump makers and distributors. Learn how to combine Spanish technology with Chinese OEM production for powerful, cost‑effective pool cleaning product lines.<br />

Discover why Germany is a leading hub for Pool Cleaning Equipment Manufacturers and Suppliers. Learn about top German brands, OEM opportunities, energy‑efficient filtration, and how global buyers can integrate German technology with Asian OEM factories to build profitable, high‑performance pool product lines.<br />

Explore France's leading Pool Cleaning Equipment Manufacturers and Suppliers, including Aqualux, ACIS, CCEI, and APF. Learn about French market trends, eco‑friendly filtration, OEM opportunities, and practical tips for brands, wholesalers, and builders sourcing high‑quality pool cleaning solutions.<br />