Views: 222 Author: Tina Publish Time: 2025-10-28 Origin: Site

Content Menu

● The Factors Determining Pool Pump Lifespan

>> 1. Quality of Design and Material Selection

>> 2. Proper Sizing and Hydraulic Performance

>> 3. Environmental and Operating Conditions

● Typical Pump Lifespan: By Component

>> Pump Housing, Lids, and O-rings

● Signs That a Pool Pump Is Nearing End of Life

● Best Practices for Pool Pump Maintenance

>> Seasonal (Spring/Fall) Tasks

>> Annual and Long-term Actions

● Advanced Strategies to Extend Pool Pump Life

>> 1. Monitor and Maintain Water Chemistry

>> 2. Use a Cover and Protect Equipment

>> 3. Install Overload Protection

>> 4. Opt for Variable-Speed Technology

>> 5. Don't Ignore Even Minor Leaks

● OEM and Manufacturer Strategies for Durability and Export Success

● Troubleshooting Common Pool Pump Problems

● Pool Pump Installation and Media Integration

● Frequently Asked Questions (FAQ)

>> 1. How long does a pool pump actually last?

>> 2. What shortens a pool pump's lifespan?

>> 3. Is it worth repairing an old pump, or should I replace it?

>> 4. How often should I maintain my pool pump?

>> 5. Why choose OEM/ODM manufacturers for pool pumps?

A pool pump is the essential heart of any swimming pool system, providing continuous circulation and ensuring your water remains clean, clear, and safe. Whether your facility uses advanced sand filters, diatomaceous earth (DE) filtration, cartridge-based systems, or integrated high-premium accessories such as LED lighting and energy-efficient water pumps, the longevity of the primary pool pump directly drives maintenance costs, user satisfaction, and operational efficiency. Many manufacturers, especially those with OEM/ODM capacity for international brands and wholesale suppliers, understand that reliability and lifespan are among the most critical selling points in a pool product portfolio.

But how long can you truly expect a pool pump to last under either residential or heavy commercial use? What are the key factors that impact its useful life? This comprehensive guide examines the typical lifespan of pool pumps, maintenance practices to maximize longevity, warning signs of failure, and OEM design considerations for global manufacturers.

- Motor engineering: Counterbalanced, high-efficiency induction motors, robust windings, and sealed bearings provide a substantial boost to a pool pump's service life, especially under harsh outdoor or high-humidity environments.[10][11]

- Component durability: Pumps made with corrosion-resistant polymers, stainless steel fasteners, and UV-stabilized plastics are better suited for repeated exposure to chemicals and sunlight. Inferior materials can crack, fade, or degrade, leading to early replacement needs.

- Mechanical layout: Modular designs (where seals, impellers, and baskets are removable and replaced easily) facilitate routine servicing and extend usable years.

- An undersized or oversized pump increases operational stress. Too powerful a pump leads to excessive turbulence, cavitation, or rapid seal wear; undersized motors overheat from being overworked.[12][13][10]

- Hydraulic resistance, or "head loss," should be matched to the pool's volume and chosen filtration system to ensure steady flow and minimal stress on the motor.

- Ambient exposure: Outdoor pools subject the pump to shifting weather, freezing temperatures, and humidity—all of which challenge water-tight seals and insulation. Indoor applications typically experience longer pump life.

- Chemical environment: High chlorine or salt levels contribute to gasket, seal, and bearing wear. Attention to chemistry slows corrosion and material breakdown.[14]

- Proactive, routine care is the single most effective factor in achieving maximum pump longevity.[1][2]

- Neglected pumps—clogged baskets, dirty filters, dry or cracked o-rings—run hotter and accumulate wear more quickly.

With regular care, most residential-grade pool pumps last 8–12 years. High-end or commercial-grade units may last upwards of 15 years, though these numbers assume proactive seal and bearing replacement along the way.[11][15][10]

- Impellers—usually made from composite plastic or brass—typically need replacement once or twice in the life of a pump, especially if debris regularly bypasses the basket.[13][10]

- Shaft seals, which prevent pool water from reaching the electric motor, should be monitored seasonally. Leaky seals, left unaddressed, can cause catastrophic motor failure.

- Housings are usually the most robust component but will degrade if exposed to UV or harsh chemicals continuously.

- O-rings and gaskets dry out and crack, particularly at the pump lid. These should be replaced yearly as a precaution.

Recognizing the early warning signs of pool pump trouble lets you schedule repairs before more severe problems arise.

- Loss of Prime/Bubbles: Persistent air in the return jets, noisy operation, or the pump failing to retain water in its housing suggests air leaks—usually around the pump lid or plumbing connections.[1][10]

- Reduced Flow: Measurable drops in water pressure or visible weakness at the return jets may mean the impeller is clogged or worn, or that the motor is losing efficiency.

- Leaking Water: Wetness or pooling under the pump highlights issues with the mechanical shaft seal or housing gasket.

- Noisy Operation: Squealing, grinding, or rattling noises often indicate bad bearings or motor shaft misalignment—both costly if ignored.

- Frequent Cycling or Shutdowns: Overheating can be caused by electrical issues, blocked filters, or insufficient water flow, reducing pump life drastically.

- Spike in Energy Consumption: If your pump uses appreciably more electricity to maintain performance, internal wear or failing motors are likely culprits.[11]

Adopting regular, structured maintenance routines ensures even the most affordable pumps achieve a long service life.

- Skim debris from the water surface and empty both skimmer and pump baskets. This prevents clogs and stress on the impeller and motor.[2][5][1]

- Inspect visible pump parts and confirm no leaks or wet patches are forming.

- Clean or backwash your chosen filtration system (sand, cartridge, or DE).

- Inspect and lubricate O-rings and gasket seals with a silicone-based lubricant.[5][1]

- Conduct a thorough check for cracked baskets, loose fasteners, or signs of shaft seal leaking.

- If you're winterizing, disconnect and drain the pump, migrating it to a frost-free area.

- Inspect and, if needed, replace shaft seals, bearings, or impellers.

- Flush out filter media (replace sand or DE as recommended by the manufacturer).

- Schedule a professional inspection every 1–2 years for complete systems, particularly if noise or performance changes are observed.[5]

Proper pH, chlorine, and alkalinity balance are essential not only for swimmer safety but also for slowing material degradation of seals and metal motor windings.[14][1]

When not in use, cover your pool or its pump equipment. Shielding from UV, rain, and ice minimizes damage to both electrical and plastic components.

GFCI (Ground Fault Circuit Interrupter) and surge protectors help prevent sudden electrical faults, which can burn out motors prematurely.[15]

Variable-speed pumps adapt to current water circulation needs, running lower RPMs during off-peak times and consuming less energy. This reduces motor wear, leading to longer life and substantial operational savings for both private and commercial pools.[15][11]

Small leaks signal gasket or seal wear. Immediate attention avoids water entering the electric motor, which would necessitate costly repairs or full replacement.

For Chinese manufacturers serving international brands, wholesalers, and pool builders, engineering long-lived pool pumps provides a significant competitive edge.

- Material Innovation: Invest in new polymers, improved shaft alloys, or self-lubricating seals for enhanced performance in extreme climates.

- Interchangeable Parts: Design modular impellers, gaskets, and baskets to be compatible with a wide range of pump models and filter brands, streamlining inventory and service for overseas distributors.

- Documentation: Provide maintenance guides and replacement part catalogs tailored to each export market. Local-language troubleshooting videos and detailed exploded parts diagrams help minimize "downtime anxiety" for buyers.

- Energy Efficiency: OEMs that offer variable-speed or eco-mode options not only support global green initiatives but also make their offerings more attractive to high-end buyers, who often factor lifetime operating costs into purchasing decisions.

- End-User Education: Offer branded maintenance checklists, explainer videos, and step-by-step installation guides. Informative content reduces product returns and increases positive brand perception among foreign wholesale clients.

- Pump Won't Start: Check for tripped breakers, damaged power cords, or blown fuses first. Inspect and replace start capacitors if needed.[2][5]

- Low Water Flow: Identify and remove clogs from filters or impellers. Ensure pool water level is adequate, and confirm there are no air leaks in suction lines.

- Leaks: Replace worn O-rings, shaft seals, or cracked housing components immediately to prevent further water damage.

- Unusual Noises: Lubricate or replace bearings. Clean out any debris stuck in pump vents or motor covers to avoid overheating.

- Pump Losing Prime: Fill the pump housing with water before runs and check for air leaks or low water levels as root causes.[1]

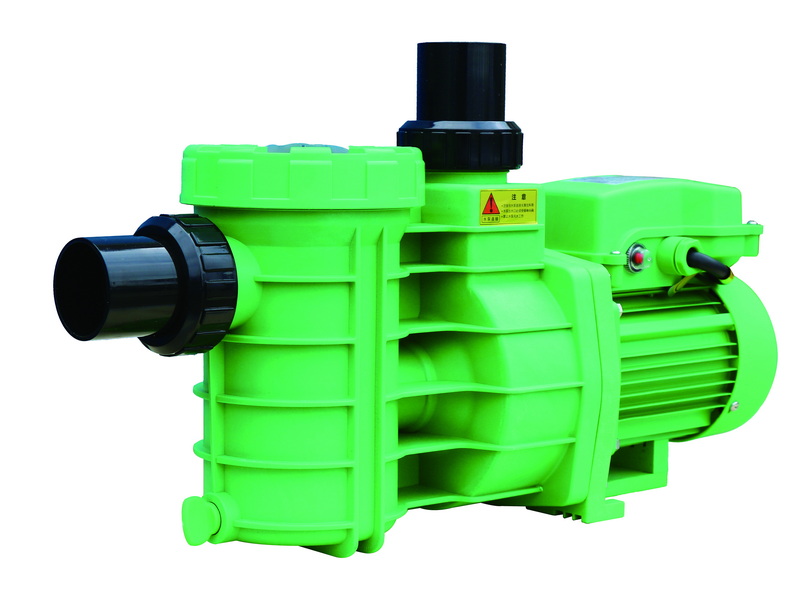

Leverage instructional videos for demonstrations of correct pump installation, maintenance routines, winterization steps, and troubleshooting basics. High-resolution images should highlight pump components, internal gaskets, and mounting configurations for both above-ground and in-ground pool systems. For web content and product catalogs, images showing real-world installations boost buyer confidence and reduce user errors in international markets.

A reliable pool pump, when selected for the right application and paired with a disciplined maintenance schedule, can deliver 8–15 years of faithful service, cutting operating costs and keeping water sparkling clear. For foreign brands and OEM/ODM factories, focusing on energy-efficient motors, modular spares, and buyer support is a pathway to success in international pool equipment markets. Routine inspections, prompt parts replacement, and informed maintenance keep pumps running smoothly—and ensure every pool, from backyard oasis to commercial resort, gets the clean, safe water it deserves.[10][5][11][15]

- With proper use and maintenance, most residential pool pumps last 8–12 years, while some commercial-grade units can reach 15 years.

- Improper pump sizing, poor water chemistry, constant motor overwork, and infrequent maintenance are leading causes of shortened pump life.

- If repairs are minor and the motor is in good condition, fixing seals or impellers can extend the pump's life. However, if the pump regularly trips breakers, vibrates excessively, or makes loud grinding noises, replacement is usually more economical.

- Perform weekly checks on baskets and visible components, monthly cleaning/lubrication of O-rings, and annual inspections and seal/impeller replacement as needed.

- OEM/ODM suppliers can customize pumps for different markets, offer modular components for easy service, and provide detailed support for international customers.

[1](https://starwatersystems.com/2025/08/04/pool-pump-maintenance/)

[2](https://lesliespool.com/blog/the-ultimate-pool-pump-maintenance-guide.html)

[3](https://poolpartstogo.com/blogs/articles/installation-and-maintenance-tips-for-pool-pump)

[4](https://www.swimmingpool.com/maintenance/pool-care-basics/)

[5](https://sqone.com/blogs/news/pool-pump-maintenance-guide)

[6](https://waterscapespools.com/essential-guide-to-pool-equipment-maintenance/)

[7](https://poolie.com/blog/maintenance/pool-pump/)

[8](https://www.doforms.com/blog/pool-maintenance-checklist/)

[9](https://www.pentair.com/en-us/education-support/water-education-center/pool-and-spa-education/pool-pump-information-guide.html)

[10](https://intheswim.com/blog/how-long-does-a-pool-pump-last.html)

[11](https://www.hilltoppools.com/how-long-do-pool-pumps-last)

[12](https://www.reddit.com/r/pools/comments/17jv94i/how_long_should_a_pump_last/)

[13](https://noisypool.com/all-about-pool-pumps-pool-pump-life-expectancy-and-common-problems/)

[14](https://www.vevor.com/zh-CN/diy-ideas/complete-guide-to-swimming-pool-filter-pump/)

[15](https://shastapoolsupply.com/blogs/news/truth-about-pool-pump-lifespan)

This guide explains how to safely increase pressure on a pool pump by restoring healthy water flow. Learn to diagnose low pressure, clean baskets and filters, fix air leaks, adjust valves and pump speed, and know when equipment upgrades or gauge replacement are necessary.<br />

This in‑depth guide explains how much it costs to replace a pool pump, covering typical price ranges, pump types, labor charges, and long‑term energy savings. Learn when to repair vs replace, DIY vs professional options, and how OEM pump and filter solutions can reduce lifetime ownership cost.<br />

Learn exactly how long to run a pool pump daily for crystal‑clear, safe water and lower energy bills. This in‑depth guide explains turnover, seasonal adjustments, single‑ vs variable‑speed schedules, energy‑saving tips, and practical examples, plus answers to common runtime questions.

This in‑depth guide explains the real reasons your swimming pool pump is not working, from power and priming issues to clogged impellers, dirty filters, and motor failures. Learn step‑by‑step troubleshooting, key maintenance tips, and when to repair or replace your pool pump.

Learn how to remove a pool pump motor safely and efficiently with this step‑by‑step guide. Discover the tools you need, how to disconnect power and plumbing, when to call a pro, and how OEM filter and pump solutions can support overseas pool brands and wholesalers.<br />

This article introduces leading Pool Cleaning Equipment Manufacturers and Suppliers in the UK, outlines their key products, and explains how international brands can combine UK distributors with Chinese OEM factories to build competitive, high‑quality private‑label pool cleaning and filtration lines.

This article outlines the leading Pool Cleaning Equipment Manufacturers and Suppliers in America, explains key product categories such as sand filters, pumps, and robotic cleaners, and shows how importers can combine U.S. brands with Chinese OEM partners to build competitive, high‑margin pool equipment portfolios.<br />

This article introduces the European market for pool equipment and accessories, profiles key Pool Cleaning Equipment Manufacturers and Suppliers, and explores OEM opportunities for Chinese factories producing sand filters, pumps, cleaners and LEDs for European brands and wholesalers.<br />

This article profiles top Pool Filter Valve Manufacturers and Suppliers in Canada, including Praher Plastics, global brands like Hayward and Carvin, and leading distributors. It explains key valve types, buying factors, and how foreign OEM factories can partner with Canadian suppliers for complete pool filtration solutions.<br />

Discover top Pool Filter Valve Manufacturers and Suppliers in Korea, from Korea Filter to SEDA, offering innovative multiport valves, OEM services, and eco-friendly designs for global pools. Explore advancements, certifications, and FAQs in this comprehensive guide to superior filtration solutions.

This article introduces leading Pool Filter Valve Manufacturers and Suppliers in Japan and Asia, covering valve types, key Japanese pool brands, OEM opportunities, and application segments. It explains how advanced engineering, strict quality control, and strong visual marketing help exporters win global pool projects.

This article introduces the main types of Pool Filter Valve Manufacturers and Suppliers serving Russia, including local distributors, industrial filter producers, global brands, and Chinese OEM partners. It explains key selection criteria, product ranges, and OEM opportunities for Russian pool projects.<br />

This article introduces the leading Pool Filter Valve Manufacturers and Suppliers in Australia, explains common valve types and technical features, highlights major distributors and OEM opportunities, and offers practical tips for international buyers sourcing compatible filtration valves and systems.

This article introduces Italy’s leading Pool Filter Valve Manufacturers and Suppliers, detailing their technologies, materials, OEM services, and application scenarios. It explains how Italian valves integrate with sand, DE, and cartridge filters and why global brands choose Italian partners for premium pool filtration solutions.<br />

This article introduces the Portuguese market for pool filtration equipment and highlights how local specialists, European brands, and Chinese OEM Pool Filter Valve Manufacturers and Suppliers cooperate to serve residential and commercial pools, offering multiport valves, filters, pumps, and customized OEM solutions.<br />

This article explains whether you can safely use pool filter sand in an aquarium, covering sand types, preparation, pros and cons, plant and fish compatibility, maintenance tips, and alternatives. It helps hobbyists choose and manage substrate using pool-grade filtration media.

This article explains when to backwash a pool filter using pressure readings, water clarity and flow as guides. It covers sand and DE filter schedules, backwash steps, common mistakes, troubleshooting cloudy water, and how OEM sand filter systems can simplify maintenance for global pool owners.<br />

This article explains what pool filter balls are, how they work, and why they are an increasingly popular alternative to sand in residential pool filters. It covers benefits, installation, maintenance, compatibility, and OEM opportunities for brands seeking high‑performance filtration solutions.<br />

This article explains how often to change a pool filter cartridge, covering typical 1–3 year lifespans, signs of wear, and factors like usage, climate, and maintenance. It shows how cleaning frequency, pressure readings, and water clarity guide replacement and highlights the value of OEM cartridge solutions.

This article explains how often to change a pool filter cartridge, covering typical 1–3 year lifespans, factors that affect replacement timing, and clear signs of wear. It outlines cleaning versus replacement, residential vs commercial schedules, and highlights OEM cartridge solutions for complete pool filtration systems.<br />