Views: 222 Author: Tina Publish Time: 2025-10-31 Origin: Site

Content Menu

● Why Does My Pool Pump Keep Shutting Off?

● Understanding the Importance of a Functioning Pool Pump

● Common Causes of a Pool Pump Shutting Off

>> Overheating or Thermal Protection

>> Mechanical Blockages and Impeller Issues

>> Low Voltage or Power Disturbances

>> Auto-Shutoffs and Control System Issues

● Step-by-Step Diagnostic Checklist

>> Safety First: Always Power Off!

● Pro Tips for OEM/ODM Pool Equipment Manufacturing

>> Sensor and Switch Integration

>> Maintenance-Friendly Engineering

>> Energy Efficiency Considerations

>> Quality Control and Preventive Maintenance

● Frequently Asked Questions (FAQ)

>> Q1: Why does my pool pump shut off suddenly after starting?

>> Q2: How can I tell if the pump motor is overheating?

>> Q3: My pump runs but the water flow is very weak. What should I check?

>> Q4: Could a faulty capacitor cause the pump to stop working?

>> Q5: Is it normal for my pool pump to make a loud noise before shutting off?

>> Q6: When should I consider calling a professional or an OEM service provider?

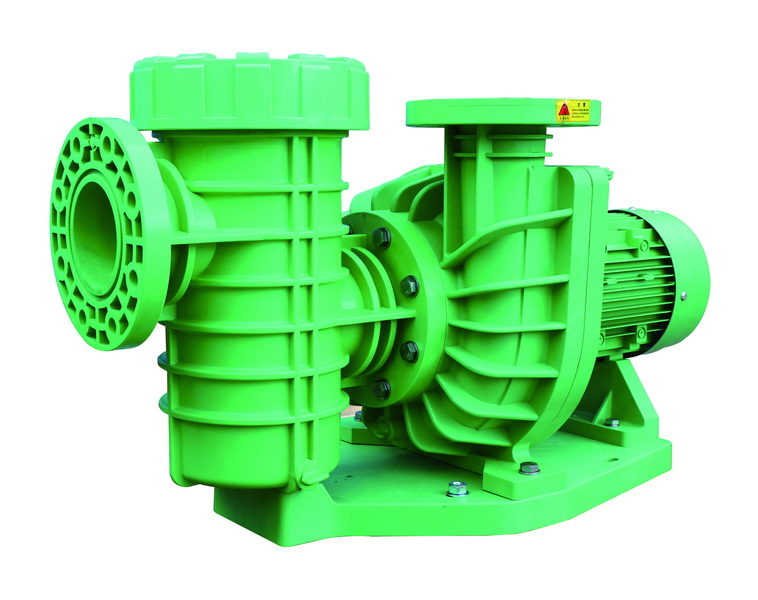

Pool pumps are the hardworking heart of any swimming pool filtration system, essential for maintaining clear, clean water and ensuring a healthy swimming environment. When a pool pump unexpectedly shuts off, it can be a source of frustration, leading to poor water quality, algae growth, and potential damage to other pool equipment. This comprehensive guide delves into the common reasons why a pool pump might keep shutting off, offering practical troubleshooting steps for homeowners, and highlighting critical design and manufacturing considerations for OEM partners. As a leading manufacturer of top-tier sand filter systems and comprehensive filtration solutions, utilizing smart machinery to produce high-quality products like pool filters (sand filters, DE filters, cartridge filters), water pumps, LED lights, and accessories, we provide OEM services to foreign brands, wholesalers, and manufacturers. Our expertise ensures reliable components that form the backbone of efficient pool systems.[1][2][11]

A properly functioning pool pump circulates water, distributing chemicals evenly and pushing water through the filter to remove debris and contaminants. This continuous circulation is vital for preventing stagnation, maintaining water hygiene, and optimizing the lifespan of your entire pool system. Any interruption in this process, especially frequent shutdowns, indicates an underlying issue that needs immediate attention.[2][10][11]

Several factors can lead to a pool pump repeatedly turning off. Identifying the root cause is the first step towards a lasting solution.[11]

Electrical problems are among the most frequent culprits behind a pump shutting off.[1]

Tripped Breakers or Blown Fuses: The pump may be drawing too much current, causing the circuit breaker to trip or a fuse to blow as a safety measure. This can be due to an overloaded circuit, a short circuit within the pump motor, or a ground fault.[2][1]

Faulty Timer Settings: If your pump is controlled by a timer, an incorrect setting or a malfunctioning timer can cause it to shut off prematurely.[1]

Loose or Worn Wiring: Poor electrical connections, frayed wires, or corroded terminals can lead to intermittent power supply, causing the pump to stop.[2]

Ground Fault Circuit Interrupter (GFCI) Issues: If the pump is connected to a GFCI outlet, a minor ground fault can cause it to trip, cutting power to the pump.[2]

Most modern pool pumps are equipped with thermal overload protectors designed to shut off the motor if it gets too hot. This prevents permanent damage to the motor windings.[7]

Poor Ventilation: Lack of adequate airflow around the motor can lead to heat buildup.[7]

Restricted Airflow: Debris, leaves, or even dense vegetation around the pump can block cooling vents.[7]

Tight Mounting or Enclosure: If the pump is installed in a small, enclosed space without proper air circulation, it will overheat.[7]

Clogged Filters or Impeller: When the pump struggles to move water due to blockages, the motor works harder, generating more heat.[11]

Low Water Level: Insufficient water flow to the pump means the motor has less water to cool it, leading to overheating.[10]

Physical obstructions within the pump itself can hinder its operation and cause it to shut down.[1]

Debris in Pump Basket: The pump's pre-filter basket collects large debris. If this basket becomes full, it restricts water flow, forcing the pump motor to overwork and potentially overheat.[9]

Clogged Impeller: The impeller is the rotating component that creates water flow. Small debris that bypasses the pump basket can get lodged in the impeller, causing it to jam or operate inefficiently. This can lead to the motor humming but not turning, or shutting off due to strain.[1][2]

Worn Bearings or Seized Motor: Over time, motor bearings can wear out, causing friction and increased heat. In severe cases, the motor can seize completely, preventing rotation and leading to immediate shutdown.[7]

Any impediment to water flow can cause the pump to struggle and eventually shut down.[10]

Dirty or Clogged Filters: Whether it's a sand filter, DE filter, or cartridge filter, a dirty filter creates back pressure, reducing water flow through the pump. This increased resistance makes the motor work harder and can cause it to overheat.[11]

Closed or Partially Closed Valves: Incorrectly positioned valves in the plumbing system can severely restrict water flow into or out of the pump.[8]

Air Leaks in Suction Line: Air being drawn into the suction side of the pump can lead to a loss of prime, causing the pump to run dry or cavitate, which can damage the impeller and cause overheating. Common culprits include loose connections, cracks in the plumbing, or a low water level in the pool.[10]

Low Pool Water Level: If the water level in the pool drops below the skimmer opening, the pump will start drawing air, leading to a loss of prime and potential shutdown.[10]

Inconsistent or inadequate power supply can also be a cause.[2]

Voltage Drop: A significant drop in voltage can prevent the motor from operating at its full capacity, causing it to draw excessive current and potentially trip a breaker.[2]

Poor Grounding: An improperly grounded system can lead to electrical irregularities and safety hazards, potentially causing the pump to shut down.[2]

Inadequate Wiring Gauge: If the wiring connected to the pump is too thin for the motor's power requirements, it can overheat and lead to voltage drops, causing the pump to trip.[2]

Modern pool systems often incorporate sophisticated controls.

Timer Misconfiguration: Incorrect programming of the pool timer can lead to the pump turning off at unintended times.[1]

Faulty Control Board: If your pump is part of a larger automation system, a malfunctioning control board can send erroneous signals, causing the pump to shut down.[2]

Remote Automation Glitches: Issues with Wi-Fi connectivity or app-based controls can disrupt scheduled operations.[2]

Leaking Seals: A worn shaft seal can allow water to leak out and air to be drawn in, leading to loss of prime and potential motor damage if not addressed.[10]

Defective Capacitor: The capacitor provides a boost to start the pump motor. If it's faulty, the motor may hum but fail to start, or struggle and eventually shut down.[2]

Aging Motor Windings: Over many years of operation, the insulation on motor windings can degrade, leading to short circuits and intermittent pump operation or failure.[7]

When your pool pump stops working, a systematic approach to troubleshooting can help pinpoint the problem efficiently.[1]

Before attempting any inspection or repair, always turn off the power to the pump at the circuit breaker. Never work on electrical components with the power on, as this poses a serious risk of electrical shock.[2]

Start with the easiest checks.[10]

Check for Obvious Leaks: Look around the pump, filter, and plumbing for any signs of water leaks.[10]

Loose Connections: Inspect all electrical wiring for loose connections or signs of burning.[2]

Blocked Vents: Ensure the motor's cooling vents are clear of debris.[7]

Pool Water Level: Verify the pool water level is above the skimmer opening.[10]

If the pump is silent or hums but doesn't start, electrical issues are likely.[2]

Verify Voltage at the Motor: Using a multimeter, carefully check the voltage supply at the pump motor terminals (with power temporarily restored and safety precautions observed).[2]

Test Capacitor: If the motor hums but doesn't start, the capacitor might be faulty. This test should be performed by a professional, as capacitors can store a dangerous electrical charge even after power is off.[2]

Inspect Timer and Breakers: Ensure the timer is set correctly and functioning. Reset any tripped circuit breakers. If a breaker repeatedly trips, there's a serious underlying electrical problem.[1]

Inspect and Clear Pump Basket: Turn off the pump, remove the lid, and clear any debris from the pump basket.[9]

Check Skimmer Basket and Pre-Filter: Ensure these are also clean to allow for proper water flow into the pump.[9]

Inspect Impeller: With the power off, carefully remove the pump housing to access the impeller. Check for any debris lodged within it and ensure it can spin freely. If it's jammed, gently clear the obstruction.[1]

Motor Shaft: Try to spin the motor shaft by hand (power off). If it feels tight or doesn't turn smoothly, it could indicate worn bearings or a seized motor.[7][2]

Confirm Valve Positions: Ensure all valves (skimmer, main drain, return lines) are open and set correctly for proper circulation.[8]

Check for Air Leaks: While the pump is running, visually inspect the suction side plumbing for bubbles in the pump basket, which indicate an air leak. You can also use shaving cream or a soapy water solution around connections to spot leaks.[10]

Filter Condition: Backwash or clean your sand, DE, or cartridge filter if the pressure gauge indicates high pressure, signaling a clogged filter.[11]

For brands, wholesalers, and manufacturers looking to provide reliable pool solutions, our factory offers advanced OEM/ODM services. Our smart manufacturing processes are designed to produce components that prevent common pump shutdown issues.[12]

Robust Electrical Enclosures: We prioritize durable, weather-resistant electrical enclosures that protect components from harsh environmental conditions.[7]

Accessible Wiring: Our designs ensure easy access for maintenance and troubleshooting, reducing service time and costs.

Easy-Access Filter Baskets: Our pump designs incorporate user-friendly, large-capacity pump baskets that are easy to clean, preventing frequent clogs and strain on the motor.[9]

Thermal Sensors: We integrate precise thermal sensors into motor designs, allowing for accurate temperature monitoring and preventing overheating through proactive shutdown mechanisms.[7]

Pressure Sensors: Built-in pressure sensors can monitor filter pressure, signaling when cleaning or backwashing is needed, thus preventing flow restrictions that lead to pump strain.[11]

Flow Switches: These ensure the pump only operates when there's sufficient water flow, protecting against dry running and cavitation.[10]

Quick-Release Clamps: Our components often feature quick-release mechanisms for easy disassembly, making maintenance and repairs straightforward for end-users and service technicians.

Clearly Labeled Ports: All plumbing ports and electrical connections are clearly labeled to prevent errors during installation and servicing.

Serviceable Motors: We design motors that allow for easier component replacement, such as capacitors or seals, extending product lifespan and reducing waste.[2]

Variable-Speed Pumps: Our OEM solutions include advanced variable-speed pump technologies that drastically reduce energy consumption while maintaining optimal filtration. These pumps also run quieter and experience less wear and tear, leading to fewer shutdowns.[11]

Efficient Motors: We use high-efficiency motors that meet international standards, ensuring peak performance with minimal energy waste.[7]

Properly Sized Equipment: Our OEM consulting ensures that pumps and filters are correctly sized for specific pool volumes and applications, preventing undersized or oversized systems that lead to inefficiency and premature failure.

Our factory employs stringent quality control measures at every stage of production, from raw material inspection to final product testing. This includes:

Routine Testing: Each pump and filter system undergoes rigorous testing to ensure it meets performance specifications and reliability standards.

Warranty Diagnostics: We offer support for diagnostic tools and procedures to quickly identify issues under warranty, reducing downtime for our OEM partners.

Traceability: Our components are fully traceable, allowing for swift identification and resolution of any manufacturing-related issues.

A pool pump that repeatedly shuts off is a clear signal that something is amiss within your pool system. By systematically troubleshooting electrical, overheating, mechanical, and flow restriction issues, most problems can be identified and resolved. Regular maintenance and attentive care are crucial for the longevity and efficiency of your pool pump.[1][10]

For foreign brands, wholesalers, and manufacturers seeking dependable, high-performance pool equipment, our factory offers unparalleled OEM services. We leverage smart machinery and 18 years of manufacturing experience to produce superior sand filter systems, DE filters, cartridge filters, water pumps, LED lights, and accessories. Our commitment to quality, energy efficiency, and advanced design ensures that your products will stand out in the market, providing reliable filtration solutions that keep pools pristine and operations smooth. Partner with us to deliver excellence in pool technology.

A: This could be due to a tripped circuit breaker, an overheating motor, an air lock in the pump, or a clogged impeller. It's important to inspect electrical connections, ensure proper ventilation around the motor, and clear any obstructions in the pump basket or impeller.[1][7][2]

A: You can carefully touch the motor housing (when the pump is off and cooled down) to see if it's unusually hot. Other signs include a burning smell or the pump shutting off after running for a short period. Thermal overload protectors are designed to trip when temperatures reach unsafe levels.[7]

A: Weak water flow often points to a restriction in the system. Check if your filter is dirty and needs cleaning or backwashing. Also, inspect all valves to ensure they are fully open, look for air leaks in the suction line (bubbles in the pump basket), and ensure the pump impeller is clear of debris.[11][10]

A: Yes, a defective capacitor is a common cause of pump motor issues. If the capacitor is failing, the motor might hum loudly but fail to start, or it might start but struggle and eventually shut down. Capacitors should be replaced by a qualified technician due to the stored electrical charge.[2]

A: No, loud noises such as grinding, squealing, or humming (without starting) are signs of a problem. These could indicate worn motor bearings, a jammed impeller, or an electrical issue like a failing capacitor. Address these noises promptly to prevent further damage.[2]

A: If you have gone through the troubleshooting steps and cannot identify or resolve the issue, or if you suspect a major electrical fault or internal motor damage, it's best to call a qualified pool professional. For brands and wholesalers, contacting an OEM service provider like us is ideal for customizing or bulk ordering reliable, high-performance pool filtration components designed to prevent such issues from the outset.[1]

[1](https://lesliespool.com/blog/pool-pump-troubleshooting-guide.html)

[2](https://intheswim.com/blog/pool-pump-troubleshooting-guide.html)

[3](https://mrpoolman.com.au/blogs/news/the-only-pool-pump-troubleshooting-guide-you-ll-need)

[4](https://www.poolzonegc.com.au/post/pool-pump-issues-a-comprehensive-guide-to-troubleshooting)

[5](https://www.youtube.com/watch?v=RHFSJ4xu-3g)

[6](https://fibreglasspoolssydney.com.au/pool-pump-troubleshooting-guide/)

[7](https://acim.nidec.com/motors/usmotors/-/media/usmotors/documents/literature/ebooks-and-articles/pool-troubleshooting-ebook-120220.ashx?la=en)

[8](https://leisurepools.com.au/wp-content/uploads/2020/10/Equipment-Accessory_INSNRG_Variable_Speed_Pump_OwnersManual.pdf)

[9](https://www.poolsmarttexas.com/blog/tried-to-fix-pool-pump-now-wont-start)

[10](https://coasttocoastpoolservices.com/blog/pool-pump-troubleshooting/)

[11](https://pleasantpools.com/5-most-common-pool-pump-problems-and-solutions/)

[12](https://www.archiexpo.cn/cat/chi-shui-liao-spa/chi-guo-lu-qi-JB-1955-_2.html)

This guide explains how to safely increase pressure on a pool pump by restoring healthy water flow. Learn to diagnose low pressure, clean baskets and filters, fix air leaks, adjust valves and pump speed, and know when equipment upgrades or gauge replacement are necessary.<br />

This in‑depth guide explains how much it costs to replace a pool pump, covering typical price ranges, pump types, labor charges, and long‑term energy savings. Learn when to repair vs replace, DIY vs professional options, and how OEM pump and filter solutions can reduce lifetime ownership cost.<br />

Learn exactly how long to run a pool pump daily for crystal‑clear, safe water and lower energy bills. This in‑depth guide explains turnover, seasonal adjustments, single‑ vs variable‑speed schedules, energy‑saving tips, and practical examples, plus answers to common runtime questions.

This in‑depth guide explains the real reasons your swimming pool pump is not working, from power and priming issues to clogged impellers, dirty filters, and motor failures. Learn step‑by‑step troubleshooting, key maintenance tips, and when to repair or replace your pool pump.

Learn how to remove a pool pump motor safely and efficiently with this step‑by‑step guide. Discover the tools you need, how to disconnect power and plumbing, when to call a pro, and how OEM filter and pump solutions can support overseas pool brands and wholesalers.<br />

This article introduces leading Pool Cleaning Equipment Manufacturers and Suppliers in the UK, outlines their key products, and explains how international brands can combine UK distributors with Chinese OEM factories to build competitive, high‑quality private‑label pool cleaning and filtration lines.

This article outlines the leading Pool Cleaning Equipment Manufacturers and Suppliers in America, explains key product categories such as sand filters, pumps, and robotic cleaners, and shows how importers can combine U.S. brands with Chinese OEM partners to build competitive, high‑margin pool equipment portfolios.<br />

This article introduces the European market for pool equipment and accessories, profiles key Pool Cleaning Equipment Manufacturers and Suppliers, and explores OEM opportunities for Chinese factories producing sand filters, pumps, cleaners and LEDs for European brands and wholesalers.<br />

This article profiles top Pool Filter Valve Manufacturers and Suppliers in Canada, including Praher Plastics, global brands like Hayward and Carvin, and leading distributors. It explains key valve types, buying factors, and how foreign OEM factories can partner with Canadian suppliers for complete pool filtration solutions.<br />

Discover top Pool Filter Valve Manufacturers and Suppliers in Korea, from Korea Filter to SEDA, offering innovative multiport valves, OEM services, and eco-friendly designs for global pools. Explore advancements, certifications, and FAQs in this comprehensive guide to superior filtration solutions.

This article introduces leading Pool Filter Valve Manufacturers and Suppliers in Japan and Asia, covering valve types, key Japanese pool brands, OEM opportunities, and application segments. It explains how advanced engineering, strict quality control, and strong visual marketing help exporters win global pool projects.

This article introduces the main types of Pool Filter Valve Manufacturers and Suppliers serving Russia, including local distributors, industrial filter producers, global brands, and Chinese OEM partners. It explains key selection criteria, product ranges, and OEM opportunities for Russian pool projects.<br />

This article introduces the leading Pool Filter Valve Manufacturers and Suppliers in Australia, explains common valve types and technical features, highlights major distributors and OEM opportunities, and offers practical tips for international buyers sourcing compatible filtration valves and systems.

This article introduces Italy’s leading Pool Filter Valve Manufacturers and Suppliers, detailing their technologies, materials, OEM services, and application scenarios. It explains how Italian valves integrate with sand, DE, and cartridge filters and why global brands choose Italian partners for premium pool filtration solutions.<br />

This article introduces the Portuguese market for pool filtration equipment and highlights how local specialists, European brands, and Chinese OEM Pool Filter Valve Manufacturers and Suppliers cooperate to serve residential and commercial pools, offering multiport valves, filters, pumps, and customized OEM solutions.<br />

This guide explains how to backwash a sand pool filter step by step, when to do it based on pressure readings, and how long to run backwash and rinse cycles. It also covers common mistakes, signs that filter sand needs replacement, and key differences among sand, DE, and cartridge filters.

This article explains how often to change or clean pool filters by type, using pressure-gauge thresholds and real-world conditions. It covers cartridge, sand, and DE filter intervals, step-by-step maintenance, lifespan signs, seasonal planning, and how OEM-sized systems can reduce maintenance while keeping water crystal clear.

This in‑depth guide explains how long pool filter cartridges last, what really affects their lifespan, and the key signs it is time to replace them. Learn practical maintenance tips, filter comparisons, and OEM insights for brands, wholesalers, and pool professionals.<br />

This guide explains how to change the sand in a pool filter step by step, from shutdown and disassembly to removing old sand, inspecting laterals, adding new media, and restarting the system. It covers safety gear, sand selection, backwashing, and common FAQs for clear, safe DIY maintenance.

This article explains practical ways to hide pool filters and equipment using landscaping, fences, sheds, benches, faux rocks, and acoustic barriers. It highlights safety clearances, ventilation, and visual media ideas, helping homeowners and buyers integrate filtration systems into attractive backyards.