Views: 222 Author: Tina Publish Time: 2025-10-18 Origin: Site

Content Menu

● Why Proper Pool Pump Runtime Matters in Summer

● Recommended Pool Pump Running Time

● How Temperature Affects Pump Runtime

● Best Times of Day to Run Your Pool Pump

● Calculating Ideal Pump Runtime

● Key Factors Influencing Runtime

● Enhancing Circulation with Energy-Efficient Strategies

● Pump Types and Their Impact on Runtime

● Pool Pump Maintenance Tips for Summer

● Pool Upgrades for Improved Efficiency

● Frequently Asked Questions (FAQs)

>> 1. How long should I run my pool pump during summer?

>> 2. Why increase runtime after storms or pool parties?

>> 3. Are variable speed pumps worth the investment?

>> 4. How can I reduce energy costs while running the pump longer?

>> 5. When should I clean or replace pool filters?

Maintaining a clean and healthy swimming pool during the hot summer months is essential for enjoying your outdoor space. One of the critical factors in pool maintenance is how long to run the pool pump each day. A properly timed pump schedule ensures water clarity, helps distribute chemicals evenly, and prevents algae growth.

Summer heat intensifies pool usage, promotes algae growth, and accelerates the accumulation of debris. Running your pool pump sufficiently each day keeps water clean and safe by circulating and filtering the water effectively. However, too short a runtime risks water quality issues, while too long a runtime results in high energy bills. Proper circulation helps prevent stagnant areas where algae and bacteria can grow, maintaining a safe swimming environment.

For most residential pools, running the pump 8 to 10 hours daily during summer is effective. This duration achieves at least one complete water turnover every 24 hours, which means all the pool water passes through your filter system, keeping it clean.

- Larger or heavily used pools might require up to 12 hours per day.

- On exceptionally hot days or after heavy pool activity (e.g., gatherings or parties), consider increasing runtime.

Algae thrive in warm, stagnant water. As air temperature rises, the pool water heats up, requiring longer pump operating times to maintain circulation and prevent algae buildup. A practical rule is to run the pump for 1 hour for every 10°F increase in air temperature. For example, at 90°F air temperature, running the pump around 9 hours helps maintain water clarity and chemical balance throughout the day.

Running the pool pump during the hottest parts of the day (mid-morning to mid-afternoon) is beneficial because it helps slow algae growth and improves chemical distribution when the sun encourages algae proliferation. Alternatively, splitting the pump runtime between daytime and evening hours can optimize both chemical effectiveness and energy use.

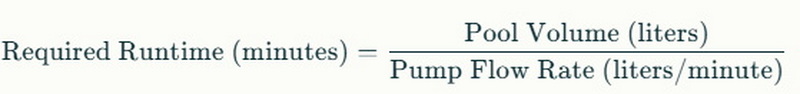

To precisely determine your pump's ideal runtime for summer, calculate based on your pool volume and pump flow rate:

For example, if your pool holds 60,000 liters and your pump flow rate is 200 liters per minute:

Since summer often demands multiple turnovers to maintain cleanliness, running the pump for around 10 hours ensures two full circulations daily, enough for warm-temperature water care.

Several factors affect the optimal pump running time:

- Pool size: Larger pools need longer filtering times.

- Pump efficiency: Pumps with lower flow rates require more runtime.

- Environmental debris: Pools near trees or gardens need extended filtering due to added organic matter.

- Pool usage: Heavy swimmer activity introduces contaminants requiring longer circulation.

Adjusting runtime based on these factors and regularly checking water clarity is vital.

While summer mandates longer run times, energy efficiency optimizations can reduce costs:

- Use a pool cover: Reduces debris and algae growth, shortening needed runtime.

- Run pump during off-peak energy hours: Morning or nighttime operation lowers electricity expenses.

- Maintain clean filters: Clogged filters decrease flow and force longer runtimes; clean or backwash weekly.

Incorporating these measures helps balance pool health with energy conservation.

- Single-speed pumps: Typically require 8–12 hours daily but consume more power due to constant full-speed operation.

- Variable speed pumps: Offer energy savings by running longer at lower speeds for filtration and switching to higher speeds only when needed, such as for cleaning cycles. Though initial cost is higher, variable speed pumps often lead to lower total energy usage and longer equipment lifespan.

Proper maintenance ensures your pump operates efficiently during heavy summer use:

- Keep pump area clear: Remove debris and vegetation around the pump to prevent overheating.

- Inspect seals and gaskets: Lubricate and replace worn parts to avoid air leaks.

- Clean pump basket frequently: Prevents clogging and maintains water flow.

- Schedule seasonal checks: Inspect motor, electrical connections, and pressure gauges to catch issues early.

These steps prevent breakdowns and optimize filtration effectiveness.

Summer weather conditions and activities call for flexible scheduling:

- After storms or heavy rains, increase runtime to clear added debris.

- Following pool parties or increased swimmer traffic, extend filtration to maintain water balance.

- During heat waves, longer operation helps combat accelerated algae growth.

Modern programmable timers and smart pool controllers allow customized schedules that vary daily or weekly, maximizing efficiency and pool health.

If your pump is older or inefficient, consider upgrading to:

- Variable speed pumps: Best for energy savings and tailored operation.

- Automated pool cleaners: Reduce pump pressure and runtime by mechanically removing debris.

- Energy-efficient filters: Enhance flow rates and reduce strain on pumps.

These investments improve performance and reduce running costs over time.

Running your pool pump for 8 to 10 hours per day during summer ensures comprehensive water circulation and filtration, essential for maintaining clean, clear, and safe pool water. Factors like pool size, usage habits, temperature, and surrounding environment may require adjustments, with larger or heavily used pools sometimes needing up to 12 hours of runtime. Choosing a variable speed pump and implementing energy-saving strategies such as running during off-peak hours or using a pool cover can balance water quality and energy costs effectively. Regular maintenance and flexible scheduling based on weather and pool use further optimize your pool's health throughout the summer months.

Typically, 8 to 10 hours per day is recommended to ensure proper water filtration and circulation during the summer season. Bigger or heavily used pools may need up to 12 hours.

Storms introduce debris and contaminants; pool parties increase swimmer load and chemical demand. Increasing runtime helps maintain water clarity and chemical balance.

Yes, variable speed pumps consume less energy while providing effective filtration. They allow for longer runtimes at lower speeds, saving on electricity bills.

Use a pool cover to reduce debris, run the pump during off-peak hours, and keep filters clean for better efficiency.

Clean or backwash filters weekly during summer or when the pressure gauge rises by 8-10 psi above normal, to maintain optimal water flow.

[1](https://guyrobertlandscape.com/summer-pool-pump-runtime-guide/)

[2](https://www.zodiac.com.au/pool-and-spa-guides/top-question-our-customers-ask-how-long-should-i-run-my-pump-for)

[3](https://starwatersystems.com/2025/08/04/pool-pump-maintenance/)

[4](https://bluewaterchemical.com/how-often-should-you-run-your-pool-pump/)

[5](https://primalpoolcare.com/blog/how-long-should-i-run-my-pool)

[6](https://darwinpools.com.au/how-long-to-run-pool-pump-in-summer-australia/)

[7](https://www.royalpoolsandspas.com/mid-summer-pool-maintenance/)

[8](https://professionalaquaticservices.com/run-your-pool-pump-each-day/)

This guide explains how to safely increase pressure on a pool pump by restoring healthy water flow. Learn to diagnose low pressure, clean baskets and filters, fix air leaks, adjust valves and pump speed, and know when equipment upgrades or gauge replacement are necessary.<br />

This in‑depth guide explains how much it costs to replace a pool pump, covering typical price ranges, pump types, labor charges, and long‑term energy savings. Learn when to repair vs replace, DIY vs professional options, and how OEM pump and filter solutions can reduce lifetime ownership cost.<br />

Learn exactly how long to run a pool pump daily for crystal‑clear, safe water and lower energy bills. This in‑depth guide explains turnover, seasonal adjustments, single‑ vs variable‑speed schedules, energy‑saving tips, and practical examples, plus answers to common runtime questions.

This in‑depth guide explains the real reasons your swimming pool pump is not working, from power and priming issues to clogged impellers, dirty filters, and motor failures. Learn step‑by‑step troubleshooting, key maintenance tips, and when to repair or replace your pool pump.

Learn how to remove a pool pump motor safely and efficiently with this step‑by‑step guide. Discover the tools you need, how to disconnect power and plumbing, when to call a pro, and how OEM filter and pump solutions can support overseas pool brands and wholesalers.<br />

This article introduces leading Pool Cleaning Equipment Manufacturers and Suppliers in the UK, outlines their key products, and explains how international brands can combine UK distributors with Chinese OEM factories to build competitive, high‑quality private‑label pool cleaning and filtration lines.

This article outlines the leading Pool Cleaning Equipment Manufacturers and Suppliers in America, explains key product categories such as sand filters, pumps, and robotic cleaners, and shows how importers can combine U.S. brands with Chinese OEM partners to build competitive, high‑margin pool equipment portfolios.<br />

This article introduces the European market for pool equipment and accessories, profiles key Pool Cleaning Equipment Manufacturers and Suppliers, and explores OEM opportunities for Chinese factories producing sand filters, pumps, cleaners and LEDs for European brands and wholesalers.<br />

This article profiles top Pool Filter Valve Manufacturers and Suppliers in Canada, including Praher Plastics, global brands like Hayward and Carvin, and leading distributors. It explains key valve types, buying factors, and how foreign OEM factories can partner with Canadian suppliers for complete pool filtration solutions.<br />

Discover top Pool Filter Valve Manufacturers and Suppliers in Korea, from Korea Filter to SEDA, offering innovative multiport valves, OEM services, and eco-friendly designs for global pools. Explore advancements, certifications, and FAQs in this comprehensive guide to superior filtration solutions.

This article introduces leading Pool Filter Valve Manufacturers and Suppliers in Japan and Asia, covering valve types, key Japanese pool brands, OEM opportunities, and application segments. It explains how advanced engineering, strict quality control, and strong visual marketing help exporters win global pool projects.

This article introduces the main types of Pool Filter Valve Manufacturers and Suppliers serving Russia, including local distributors, industrial filter producers, global brands, and Chinese OEM partners. It explains key selection criteria, product ranges, and OEM opportunities for Russian pool projects.<br />

This article introduces the leading Pool Filter Valve Manufacturers and Suppliers in Australia, explains common valve types and technical features, highlights major distributors and OEM opportunities, and offers practical tips for international buyers sourcing compatible filtration valves and systems.

This article introduces Italy’s leading Pool Filter Valve Manufacturers and Suppliers, detailing their technologies, materials, OEM services, and application scenarios. It explains how Italian valves integrate with sand, DE, and cartridge filters and why global brands choose Italian partners for premium pool filtration solutions.<br />

This article introduces the Portuguese market for pool filtration equipment and highlights how local specialists, European brands, and Chinese OEM Pool Filter Valve Manufacturers and Suppliers cooperate to serve residential and commercial pools, offering multiport valves, filters, pumps, and customized OEM solutions.<br />

This article explains whether you can safely use pool filter sand in an aquarium, covering sand types, preparation, pros and cons, plant and fish compatibility, maintenance tips, and alternatives. It helps hobbyists choose and manage substrate using pool-grade filtration media.

This article explains when to backwash a pool filter using pressure readings, water clarity and flow as guides. It covers sand and DE filter schedules, backwash steps, common mistakes, troubleshooting cloudy water, and how OEM sand filter systems can simplify maintenance for global pool owners.<br />

This article explains what pool filter balls are, how they work, and why they are an increasingly popular alternative to sand in residential pool filters. It covers benefits, installation, maintenance, compatibility, and OEM opportunities for brands seeking high‑performance filtration solutions.<br />

This article explains how often to change a pool filter cartridge, covering typical 1–3 year lifespans, signs of wear, and factors like usage, climate, and maintenance. It shows how cleaning frequency, pressure readings, and water clarity guide replacement and highlights the value of OEM cartridge solutions.

This article explains how often to change a pool filter cartridge, covering typical 1–3 year lifespans, factors that affect replacement timing, and clear signs of wear. It outlines cleaning versus replacement, residential vs commercial schedules, and highlights OEM cartridge solutions for complete pool filtration systems.<br />