Views: 222 Author: Tina Publish Time: 2025-09-10 Origin: Site

Content Menu

>> 6. Frequent Tripping of Circuit Breaker

>> Pressure and Flow Rate Checks

● Common Causes of Pool Pump Problems

● When to Replace Your Pool Pump

>> 1. How often should I service my pool pump?

>> 2. Can a bad pool pump damage my filter?

>> 3. What is the average lifespan of a pool pump?

>> 4. Is it worth repairing a bad pool pump?

>> 5. Can a pool pump run continuously?

A well-functioning pool pump is essential for keeping your swimming pool clean and clear. If your pool pump starts to fail, it can lead to dirty water, poor circulation, and eventually costly repairs. This comprehensive guide explains how to tell if your pool pump is bad, covering common signs, troubleshooting tips, and maintenance advice. Whether you own a sand filter, DE filter, or cartridge filter system, this article will help you diagnose potential pump issues before they escalate.

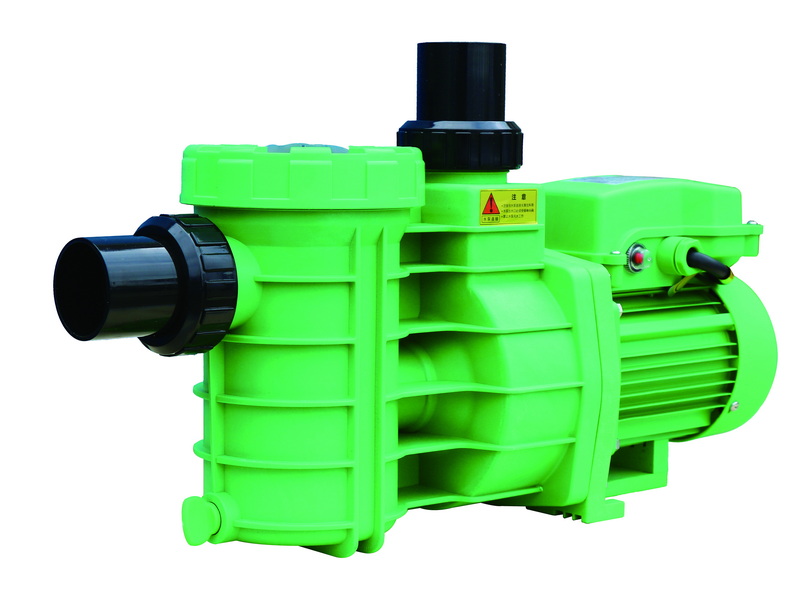

Pool pumps circulate water through your pool's filtration system, helping to remove debris, bacteria, and algae. The pump draws water from the pool, pushes it through the filter (sand, DE, or cartridge), then returns the clean water. A failing pump will disrupt this process, leading to water quality problems and potential damage to pool equipment.

Pool pumps typically consist of several key components: the motor, impeller, pump housing, seal plate, and pump basket. The motor powers the impeller, which creates water flow by drawing water into the pump and pushing it through the filter and back to the pool. Proper function of each part is necessary to maintain efficient pool circulation.

Listen for grinding, squealing, or rattling sounds coming from the pump. These noises often indicate worn bearings, motor problems, or debris stuck in the impeller. Sometimes, noisy operation may be a sign of cavitation—a condition where air bubbles form and collapse in the water flow inside the pump, damaging the impeller and reducing efficiency.

If the pump does not start when switched on, check for electrical issues such as tripped circuit breakers, blown fuses, or faulty wiring first. Persistent failure to start may signal a faulty motor, capacitor problem, or internal electrical damage. Some pumps have a reset button—try resetting if available.

Reduced water flow from the pump can result from clogs in the skimmer, filter, or pump basket, or from a failing impeller. No flow at all could indicate a bad motor, broken shaft seal, or air leaks in the suction line. If the water level in the pool is too low, the pump may lose prime and fail to move water correctly.

If the pump motor becomes very hot to the touch and shuts off automatically, it may be overheating due to electrical issues, blocked ventilation, or lack of lubrication for the motor bearings. Overheating increases wear and reduces the lifespan of the pump motor. Make sure the pump housing has proper airflow and that the motor is not exposed to direct sunlight for long periods.

Visible leaks around your pump housing or seal plate often indicate worn seals, cracked pump parts, or gasket failure. Water leaks reduce pump efficiency, damage electrical components, and can cause structural corrosion. Early detection of leaks is important to prevent costly replacements.

If your pool pump frequently trips the circuit breaker, it may indicate overloaded circuits, motor short circuits, or electrical faults within the pump motor or wiring. This issue not only stops pool circulation but also poses an electrical hazard and requires immediate attention.

Excessive vibrations or shaking during operation can signal unbalanced impellers, worn motor bearings, or loose mounting bolts. Persistent vibration can lead to further mechanical damage or misalignment of pump components.

Use a pressure gauge installed on the filter system to monitor pressure before and after the pump. Significant pressure drops indicate blockages or pump malfunctions. A flow meter can also help confirm if the pump is providing the correct water flow rates according to manufacturer specifications.

Test the pool pump motor and capacitor with a multimeter to check continuity and resistance values. An open circuit or extreme resistance can suggest internal motor winding failure or capacitor malfunction. Testing helps pinpoint electrical faults that cause no-start or intermittent operation.

Remove the pump lid and observe the impeller while the pump is running (if safe to do so). Look for debris lodged in the impeller or signs of cracked or worn impeller vanes. Check for water leaking around the motor shaft or seal plate.

- Regularly clean the pump basket and skimmer baskets to avoid clogging. Debris caught here can reduce water flow and strain the pump motor.

- Inspect and replace worn pump seals and gaskets to prevent leaks and maintain suction efficiency.

- Lubricate O-rings and shaft seals with silicone-based grease suitable for pool equipment to extend seal life.

- Ensure the motor housing ventilation openings are free of dust, dirt, and obstructions to prevent overheating.

- Check electrical connections periodically for corrosion or loose wiring that can cause intermittent faults or shorts.

- Clean the pump motor exterior occasionally to maintain cooling efficiency.

- Consider installing a variable speed pump to optimize energy use and reduce motor stress compared to single-speed pumps.

- Maintain proper water levels in the pool to ensure the pump remains primed and does not run dry, which damages seals.

- Dirt and debris clogging the pump basket or filter

- Air leaks in suction lines causing loss of prime

- Motor bearing wear leading to noise and motor failure

- Electrical component failures like capacitors and wiring shorts

- Seal and gasket deterioration causing leaks

- Impeller damage or blockages affecting flow

- Incorrect pump sizing or installation leading to premature wear

Understanding these causes helps pool owners take proactive steps to maintain their pumps.

If your pool pump consistently shows signs of failure like frequent overheating, motor hums without spinning, persistent leaks despite maintenance, or repeated electrical failures, it's time to invest in a replacement. Modern pool pumps offer improved energy efficiency, quieter operation, and enhanced durability. Upgrading can save money on utility bills and lower maintenance effort.

Look for pumps that match your pool size and filtration system requirements. Energy-efficient variable speed models provide optimal flow control and reduce energy consumption by up to 70% compared to traditional single-speed pumps.

Knowing how to tell if your pool pump is bad enables you to address problems early and maintain a clean, healthy pool environment. Pay attention to unusual noises, water flow issues, leaks, overheating, and electrical symptoms. Regular maintenance including cleaning, lubricating, and inspection can prolong your pump's life and prevent costly downtime. When repairs become too frequent or ineffective, replacing your pump with a newer, energy-efficient model is the best investment to ensure consistent pool performance.

It is recommended to service the pump at least once per season and clean pump baskets monthly to prevent clogging.

Yes, a malfunctioning pump can reduce water flow causing filter clogging or damage over time.

Typically, pool pumps last between 8 to 12 years with proper maintenance.

Minor repairs such as replacing seals or impellers are cost-effective; however, motor failures usually require pump replacement.

While pools require daily circulation, continuous operation can wear out components faster. Using a timer or variable speed pump optimizes run time and energy efficiency.

content is empty!